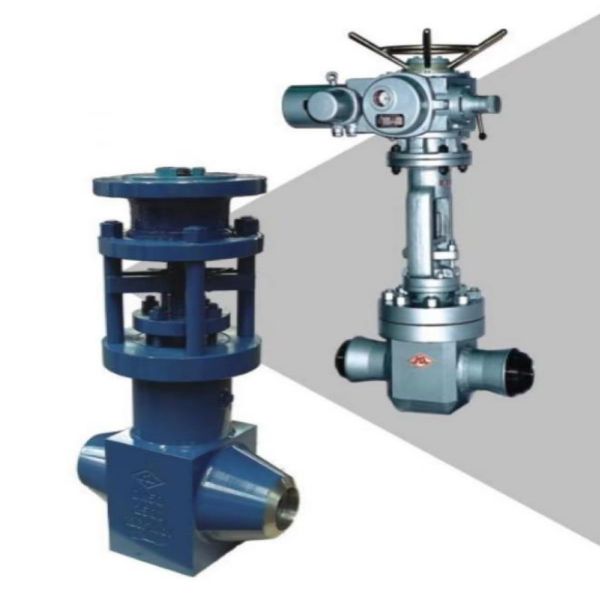

Isiteshi Samandla Sokusakaza Sensimbi Esezingeni Eliphezulu I-Globe Valve

Izici

1. Ngokuvumelana ne-NB/T 47044 kanye ne-ASME B16.34

2. I-mesh pole iyamelana nokuhuzuka, imelana nezinga lokushisa eliphezulu futhi imelana nokugqwala ngemva kokumiswa kwe-conditioning kanye ne-chlorination.

3. Ukushuba komzimba we-mesh kusebenzisa isakhiwo sokuvala ingcindezi(UKUVALWA KWEZINKUNZI), futhi ukucindezela komgodi ongaphakathi obanzi okuphezulu kuba ngcono.

4. Isiqondiso sokugeleza okuphakathi sisebenzisa i-inlet ephezulu kanye ne-outlet ephansi, futhi ukulawulwa kwesiliva kuthatha isakhiwo esilawula kabili, esine-torque encane yokuqala futhi kulula ukuyivula.

5. Indawo yokubeka uphawu yesihlalo esibanzi nebhodi yenziwe nge-carbide ene-cemented surfacing noma i-sub item welding, enokumelana nokushisa okuphezulu, ukumelana nokuhuzuka nokumelana nokuklwebheka.

• Okujwayelekile: 7*84: NB/T 47044, ASME B16.34.JB/T 3595. DL/T 531

• Ingcindezi Yokuzisholo: PN160-PN630 (CLASS900- CLASS3500) , P54100V, P54140V, P54170V, P57100V, P57140V, P57170V

•NominalDimension:DN50~Dx500 (2”-14”)

• Okubalulekile:

1.WCB, ZG20CrMo, Cr5Mo, ZG20CrMoV, ZG15Cr1MoV

2. 25#, 12Cr1MoV

3. ASTM A216 WCB, ASTM A217 WC6, ASTM A217 WC9, ASTM A217 C12A

4. ASSTM A105, ASTM A182 F11, ASTM A182 F22,ASTM A182 F91, ASTM A192 F92

• Izinga Lokushisa Lokusebenza:

1. WCB: - 29℃~425℃

2. Insimbi yengxubevange: - 29℃~540℃, -29℃~570℃

3. F91:-29℃~610℃

• Abalamuli Abasebenzayo: Amanzi, I-Steam, njll

• Imodi yokuxhuma: Ukushisela

• Imodi yokudlulisa: Imanuwali, ukulinganisa kwamasondo, ugesi, umoya womoya, i-hydraulic

I-Anti-scour Globe Valve

Izici:

1.Amazinga:NB/T 47044, ASME B16.34

2. Ngemva kokucisha nokushisa kanye nokwelashwa kwe-nitrogen, induku ye-Fujian inokumelana nokushisa okuphezulu, ukumelana nokugqoka kanye nokumelana nokugqwala okuhle.

3. Yamukela isihlalo sokulungisa i-anti scour, ihholo elibanzi kanye nomkhono we-anti scour, konke okungaphansi kokwelashwa okudansa futhi okunomphumela wokulwa nokukhwabanisa futhi kungashintshwa.

4. Isiqondiso sokugeleza okuphakathi sisebenzisa i-inlet ephezulu ne-outlet ephansi, ebonakala nge-torque encane yokuvula nokuvala kanye nokuvula okulula.

5. Indawo yokuvala isihlalo somgodi kanye nephaneli yokufinyelela yenziwe nge-cobalt base hard alloy ngokufaka i-welding noma i-plasma spray welding, enokumelana nokushisa okuphezulu, ukumelana nokugqoka kanye nokumelana nokuqala.

6. Umzimba olungisayo wamukela isakhiwo sokubumba.

• Okujwayelekile: NB/T 47044, ASME B16.34,JB/T 3595, DL/T 531

• Ingcindezi Yokuzisholo: PN160-PN630(CLASS900-CLASS3500),P54100V, P54140V, P54170V, P57100V, P57140V, P57170V

• Ubukhulu Bamagama: DN10~DN100(2”-4”)

• Izinto Ezibalulekile: 1. 25#,12Cr1MoV

- ASTM A105,ASTM A182 F11,ASTM A182 F22,ASTM A182 F91,ASTM A182 F92

• Izinga Lokushisa Lokusebenza: -29℃~650℃

• Abalamuli Abasebenzayo: Amanzi, I-Steam

• Imodi yokuxhuma: I-Flange, i-Welding

• Imodi yokudlulisa: Imanuwali, ukulinganisa kwesondo, ugesi, i-Pneumatic, i-Hydraulic

Isibonisi somkhiqizo