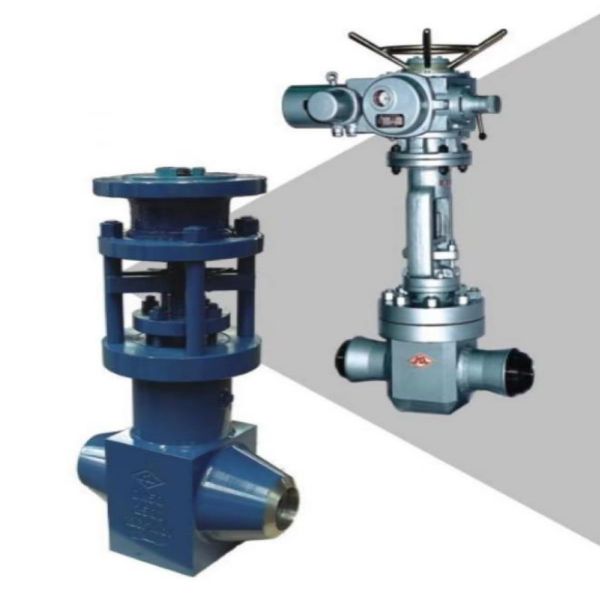

High Quality Steel Casting Power Station Globe Valve

Features

1. In accordance with NB/T 47044 and ASME B16.34

2. The mesh pole is abrasion resistant, high temperature resistant and corrosion resistant after conditioning and chlorination.

3. The tension in the mesh body use the pressure sealing structure(WOOD CLOSURE), and the higher wide body inner cavity pressure the better.

4. The medium flow direction adopts high inlet and low outlet, and the silver regulating adopts double regulating structure, which has small starting torque and easy to open.

5. The sealing surface of wide seat and board is made of cemented carbide surfacing or sub item welding, with high temperature resistance, abrasion resistance and scratch resistance.

• Standard: 7*84: NB/T 47044, ASME B16.34. JB/T 3595. DL/T 531

• Nominal Pressure: PN160-PN630 (CLASS900- CLASS3500) , P54100V, P54140V, P54170V, P57100V, P57140V, P57170V

• NominalDimension:DN50~Dx500 (2”-14”)

• Main Material:

1.WCB, ZG20CrMo, Cr5Mo, ZG20CrMoV, ZG15Cr1MoV

2. 25#, 12Cr1MoV

3. ASTM A216 WCB, ASTM A217 WC6, ASTM A217 WC9, ASTM A217 C12A

4. ASSTM A105, ASTM A182 F11, ASTM A182 F22,ASTM A182 F91, ASTM A192 F92

• Operating Temperature:

1. WCB: - 29℃~425℃

2. Alloy steel: - 29℃~540℃, - 29℃~570℃

3. F91:-29℃~610℃

• Applicable Intermediaries: Water, Steam, etc

• Connection Mode: Welding

• Transmission Mode: Manual, wheel equalizing, electric, pneumatic, hydraulic

Anti-scour Globe Valve

Features:

1.Standards:NB/T 47044, ASME B16.34

2. After quenching and tempering and nitrogen treatment, the Fujian rod has high temperature resistance, wear resistance and good corrosion resistance.

3. It adopts anti scour adjusting seat, wide hall and anti scour sleeve, which are all subject to dancing treatment and have anti scour performance and can be replaced.

4. The medium flow direction adopts high inlet and low outlet, which is characterized by small opening and closing torque and convenient opening.

5. The sealing surface of the hole seat and the access panel is made of cobalt base hard alloy by surfacing welding or plasma spray welding, with high temperature resistance, wear resistance and scratch resistance.

6. The adjusting body adopts forging structure.

• Standard: NB/T 47044, ASME B16.34,JB/T 3595, DL/T 531

• Nominal Pressure: PN160-PN630(CLASS900-CLASS3500),P54100V, P54140V, P54170V, P57100V, P57140V, P57170V

• Nominal Dimension: DN10~DN100(2”-4”)

• Main Material: 1. 25#,12Cr1MoV

- ASTM A105,ASTM A182 F11,ASTM A182 F22,ASTM A182 F91,ASTM A182 F92

• Operating Temperature: -29℃~650℃

• Applicable Intermediaries: Water, Steam

• Connection Mode: Flange, Welding

• Transmission Mode: Manual, Wheel equalizing, Electric, Pneumatic, Hydraulic

Product Display