Okpomọkụ & Nrụgide Mbelata Valves

Atụmatụ

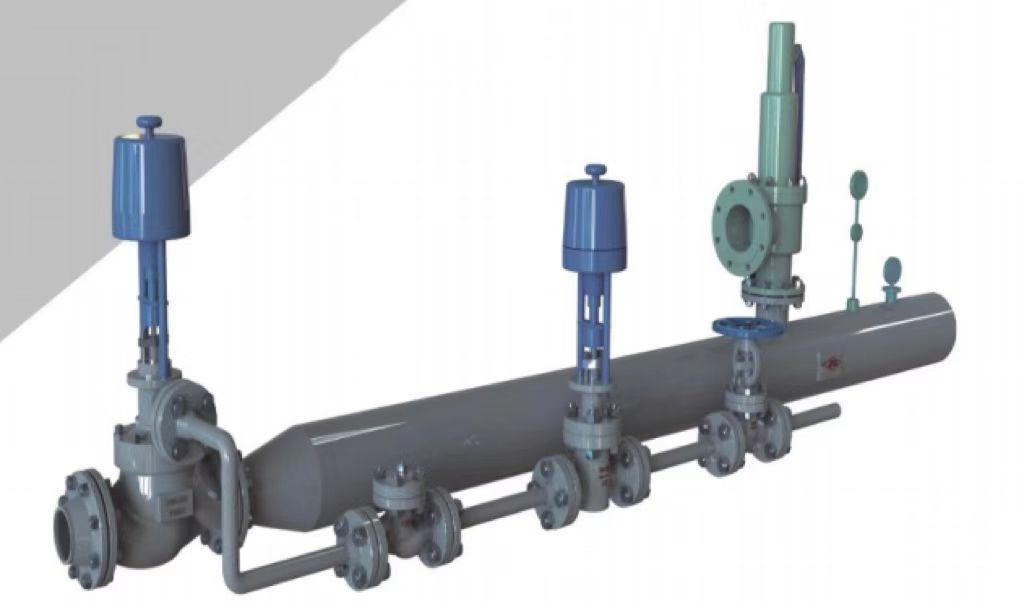

Ngwaọrụ na-ebelata okpomọkụ & nrụgide bụ ngwaahịa ọgbọ ọhụrụ emepụtara site na itinye teknụzụ dị elu na nhazi nke okpomọkụ na enyemaka nrụgide n'ụlọ na ná mba ọzọ.

Ọ mejupụtara akụkụ anọ: Okpomọkụ & Nrụgide na-ebelata valvụ, ọkpọkọ vapo, okpomọkụ na-ebelata ọkpọkọ mmiri na ngwaọrụ na-achịkwa okpomọkụ.

• Ọkọlọtọ: NB/T 47033

Ngwa:

A na-eji ngwaọrụ ndị na-ebelata okpomọkụ & nrụgide nrụgide na ụlọ ọrụ ọkụ ọkụ, ụlọ ọrụ mmepụta ihe, ọkụ ọkụ ọkụ, wdg, iji belata okpomọkụ na nrụgide nke isi (ọhụrụ) uzuoku P1 na okpomọkụ D1, nke mere na nrụgide uzuoku nke abụọ P2 na okpomọkụ T2. nwere ike iru ụkpụrụ achọrọ site na mmepụta usoro.WY usoro okpomọkụ na nrụgide mbenata ngwaọrụ na ya na-akwado akpaka akara kabinet nwere keukwu ọrụ nke nha na akara, na-ọtụtụ ebe na-eji ike ọdụ, Petrochemical, ìhè ụlọ ọrụ, metallurgy na ndị ọzọ ulo oru ngalaba nakwa dị ka obodo kpo oku na kpo oku usoro.

• nrụgide ntinye na okpomọkụ: obere nrụgide P1 ≤ 1.0MPa, T1 ≤ 300 ℃;

Ọkara mgbali P1 ≤ 4.0MPa, T1 ≤ 450℃;

Secondary elu voltaji P1 ≤ 5.4MPa.T1 ≤ 485℃;

Okpomọkụ dị elu na nrụgide dị elu P1 ≤ 20MPa, T1 ≤ 570 ℃;

• Nrụgide uzuoku nke ọpụpụ: Nrụgide uzuoku P2 na okpomọkụ T2 ga-abụ ụkpụrụ nke onye ọrụ chọrọ, na nhazi nhazi agaghị adị ala karịa 2.5.

• Oke mkpọtụ: N'oge arụ ọrụ nkịtị nke ngwaọrụ ahụ, a na-atụ mkpọtụ nke olulu mmiri 1 m n'okpuru otu ụgbọ elu kwụ ọtọ na etiti etiti nke okpomọkụ na nrụgide na-ebelata ọgụgụ ọgụgụ (nrụgide nrụgide na-ebelata) ngwaọrụ a na-atụ n'ebe dị anya nke 1 m site na ya. mgbidi ọkpọkọ, na ọkwa mkpọtụ n'ozuzu ekwesịghị ịbụ ihe karịrị 85dB (A).

Okpomọkụ & Nrụgide Mbelata Valve

Atụmatụ:

Ihe mkpuchi valvụ ahụ na-anabata usoro akara onwe ya ma ọ bụ ụdị flange, oghere ụdị uwe plunger valvụ isi, akara cone otu oche, yana ọkwa dị elu.A na-ekpuchi elu mkpuchi ahụ na carbide cemented, a na-efesa elu dị n'ime ya na ihe ndị na-eguzogide mmetụta, na-arụ ọrụ ogologo oge.The akara bụ metal ọnya gasket na mesikwuru mgbanwe graphite, a pụrụ ịdabere na akara.Enweghị mmaji.

Ngwa:

A na-eji ya maka nhazi usoro mmiri na-asọ asọ, na-eji akara a pụrụ ịdabere na ya, ọkwa dị elu na ogologo ndụ ọrụ.Mmiri na-enye uzo, ịgbasa desuperheating usoro.

• Nrụgide aha: P5450V-P57200V

• Akụkụ aha: DN50 ~ DN300

• Oke mgbanwe: 20: 1-100: 1

• Isi ihe: WCB, WC6, ZG20CrMo, 12Cr1MoV

• Ọnọdụ okpomọkụ: -29 ℃ ~ 570 ℃

• Ndị na-emekọrịta ihe: Vapo

• Ụdị njikọ: Flange, Welding

• Ụdị nnyefe: Eletriki, Pneumatic

Okpomọkụ dị elu & Mbelata Valve

Atụmatụ:

valvụ ahụ na-anabata ụdị oghere porous, na-enwe ezigbo mgbanwe, enweghị mkpọtụ na enweghị ịma jijiji.Ndị internals nwere ike ịnakwere otu-ogbo ma ọ bụ multi-stage throttling, nke na-emetụta elu-nrụgide dị iche iche ọnọdụ ọrụ.A na-emecha mbelata nrụgide na otu valvụ.N'ịtụle ọnọdụ okpomọkụ dị elu, ngbanwe nke ime na nhazi dị mma, ọrụ ahụ na-agbanwekwa.A na-emepụta mkpuchi valvụ dị ka mkpuchi na-edozi onwe ya, nke kwesịrị ekwesị maka ọnọdụ ọrụ nke okpomọkụ dị elu na mgbasa ozi nrụgide dị elu.A na-ekpuchi elu mkpuchi nke oche valve na carbide cemented, na elu nke free isi na-efesa ya na carbide cemented, nke na-eguzogide ọgwụ mgbochi ma nwee ogologo ndụ ọrụ.Otu oche valvụ cone na-ekpuchi elu, akara a pụrụ ịdabere na ya, obere ntapu ma dị mma na-ehicha onwe ya.

Ngwa:

Ntugharị na njikwa nrụgide nke ụzọ ụgbọ mmiri uzuoku na ngafe uzuoku dị ọkụ.Njikwa uzuoku na ikpo ọkụ nke sistemu ịfụ mmiri ọkụ soot.Iwu nrụgide uzuoku dị elu nke pipeline uzuoku na-ekpo ọkụ ma dị elu.

Valve Sistemu nrụgide dị elu

Atụmatụ:

A na-eji valvụ ntinye ọnụ na valvụ nlele.Mgbe ikpo ọkụ dị elu jupụtara na mmiri, nrụgide nke mmiri na-abawanye na-aga n'ihu.Mgbe nrụgide ahụ na-ebili na uru ụfọdụ, mkpanaka valvụ ahụ na-ebuli elu site n'enyemaka nke nrụgide dị iche iche na-arụ ọrụ na akụkụ valve nke valve ntinye iji mepee ọwa n'ime ọkụ ọkụ dị elu, na-ekwe ka mmiri banye n'ime nnukwu nrụgide. kpo oku.N'oge a, a na-etinye ọkụ ọkụ dị elu na-arụ ọrụ.Mgbe usoro pipeline nke onye na-ekpo ọkụ ọkụ na-agbaji na mberede, na ọkwa mmiri dị na ikpo ọkụ dị elu karịa uru a na-enye ohere, akara ngosi mmiri na-emepe oghere ngwa ngwa na imechi valve site na ngwaọrụ eletriki, condensate na-abanye na piston. cylinder n'elu valvụ ntinye, na-agbanye piston ahụ, na-agbanye relay na-achịkwa, mechie ntinye nke ikpo ọkụ dị elu, meghee uzo, na ikpo ọkụ dị elu Ngwaọrụ na-akwụsị ịgba ọsọ, na oge ọrụ dum bụ 2 sekọnd.

• Ọkọlọtọ: NB/T 47044, ASME B16.34, JB/T 3595

• Nrụgide aha: PN16-PN420(CLASS900-CLASS2500)

• Akụkụ aha: DN100~DN350(4"-14")

• Isi ihe: 1.WCB, ZG20CrMo, Cr5Mo, ZG20CrMoV

2.25#, 12Cr1MoV

3.ASTM A216 WCB, ASTM A217 WC6, ASTM A217 WC9

4.ASTM A105, ASTM A182 F11, ASTM A182 F22

• Okpomọkụ na-arụ ọrụ: 1. WCB: -29 ℃ ~ 425 ℃

2. Alloy Steel: -29 ℃ ~ 540 ℃, -29 ℃ ~ 570 ℃

• Ndị na-emekọrịta ihe: Mmiri, Steam

• Ụdị njikọ: Welding

• Ụdị nnyefe: akwụkwọ ntuziaka, eletriki, hydraulic

Valve Nnwale Hydrostatic

Atụmatụ:

A na-etinye ya n'elu ikpo ọkụ na-ekpo ọkụ nke ọkụ ọkụ na ntinye na ntinye uzuoku uzuoku nke reheater dị ka iche n'oge ule hydrostatic.Mgbe nrụgide mmiri gasịrị, wepụ ihe mgbochi ime ụlọ dị ka ọkpọkọ.Enwere ike itinye efere oghere ọzọ n'oge ule hydrostatic na-esote.

Ngwa:

1. The nrụgide onwe tightening akara Ọdịdị na-nakweere, na alaka ọkpọkọ na ma nsọtụ na-welded.

2. A na-anakwere akara akara O-mgbanaka dị larịị, na oche valve bụ nke igwe anaghị agba nchara site na ịgbado ọkụ.

3. A ga-etinye efere na-adịghị ọcha n'oge ule hydrostatic, ma wepụ ya mgbe ule hydrostatic gasịrị.Enwere ike ịme ule hydrostatic ọtụtụ.• Ọkọlọtọ: JB/T 12002,NB/T 47044 ASME B16.34

• Nrụgide aha: PN16-PN420 (CLASS150-CLASS2500), P54100V-P57200V

• Akụkụ aha: DN100~DN1000(4"-48")

• Isi ihe: 1.WCB, ZG20CrMo, Cr5Mo, ZG20CrMoV, ZG15Cr1MoV

2.25#, 12Cr1MoV

3.ASTM A216 WCB, ASTM A217 WC6, ASTM A217 WC9, ASTM A217 C12A

4.ASTM A105, ASTM A182 F11, ASTM A182 F22, ASTM A182 F91, A182 F92

• Okpomọkụ na-arụ ọrụ: 1. WCB: -29 ℃ ~ 425 ℃

2. Alloy Steel: -29 ℃ ~ 540 ℃, -29 ℃ ~ 570 ℃

3. F91: -29℃~610℃

• Ndị na-emekọrịta ihe: Mmiri, Steam

• Ụdị njikọ: Welding

• Ụdị nnyefe: /

Ngosipụta ngwaahịa