Izinga lokushisa Nokucindezela Amavavu Okwehlisa Ingcindezi

Izici

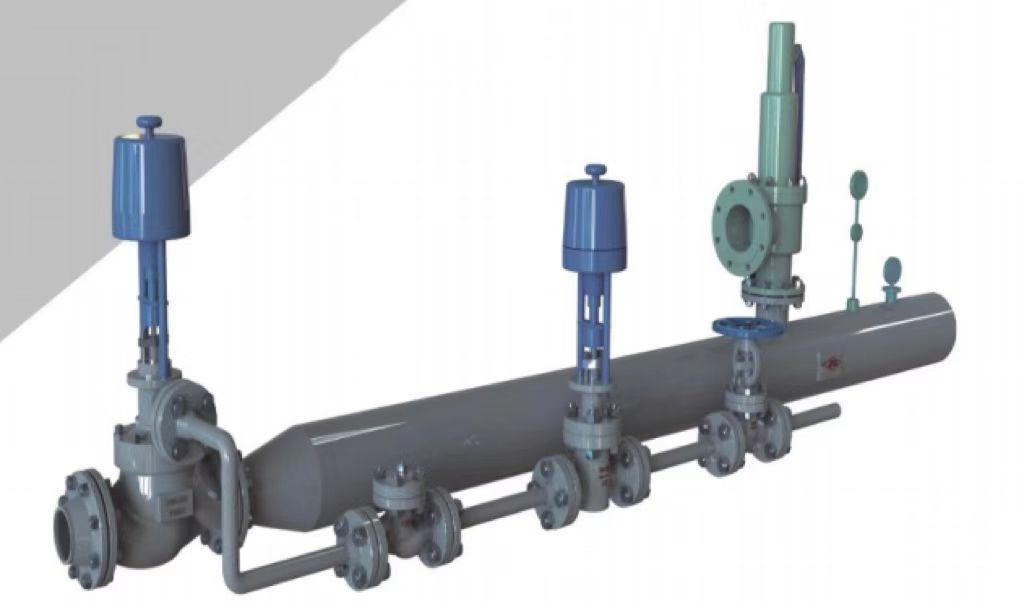

Idivayisi yokunciphisa izinga lokushisa nokucindezela umkhiqizo omusha wesizukulwane othuthukiswe ngokumunca ubuchwepheshe obuthuthukisiwe nesakhiwo sokunciphisa izinga lokushisa nokucindezela ekhaya naphesheya.

Yakhiwe izingxenye ezine: I-valve yokunciphisa izinga lokushisa nokucindezela, ipayipi lomhwamuko, ipayipi lamanzi elinciphisa izinga lokushisa kanye nedivayisi yokulawula ukushisa.

• Okujwayelekile: NB/T 47033

Izicelo:

amadivaysi okunciphisa izinga lokushisa nokucindezela asetshenziswa ezimbonini zikagesi, kumabhayela ezimboni, ezimbonini zamandla ashisayo, njll., ukunciphisa izinga lokushisa nokucindezela komfutho wesitimu oyinhloko (omusha) we-P1 nezinga lokushisa elingu-D1, ukuze umfutho wesibili wesitimu u-P2 kanye nezinga lokushisa elingu-T2. ingafinyelela amanani adingwa inqubo yokukhiqiza.Idivayisi yokunciphisa izinga lokushisa nokucindezela kochungechunge lwe-WY kanye nekhabhinethi yayo yokulawula okuzenzakalelayo esekelayo inemisebenzi ebanzi yokulinganisa nokulawula, futhi isetshenziswa kabanzi esiteshini samandla, i-petrochemical, imboni yokukhanya, i-metallurgy neminye iminyango yezimboni kanye nezinhlelo zokushisisa nokushisa zasemadolobheni.

• Ukucindezela kokungena kanye nezinga lokushisa: Ingcindezi ephansi P1 ≤ 1.0MPa, T1 ≤ 300℃;

Ingcindezi emaphakathi P1 ≤ 4.0MPa, T1 ≤ 450℃;

I-voltage ephezulu yesibili P1 ≤ 5.4MPa.T1 ≤ 485℃;

Ukushisa okuphezulu nokucindezela okuphezulu P1 ≤ 20MPa, T1 ≤ 570℃;

•Ukucindezela kwesitimu sokuphumayo: Umfutho wesitimu we-Outlet P2 kanye nezinga lokushisa elingu-T2 kuzoba amanani adingwa umsebenzisi, futhi ukunemba kokulungisa akumele kube ngaphansi kuka-2.5.

•Ibanga lomsindo: Ngesikhathi sokusebenza okuvamile kwedivayisi, umsindo womthombo oyi-1 m phansi komfula wendiza efanayo evundlile endaweni emaphakathi yezinga lokushisa nokunciphisa umfutho wokufunda (ukulawula ukunciphisa ukucindezela) idivayisi ikalwa ebangeni elingu-1 m ukusuka. udonga lwamapayipi, kanye nezinga lomsindo lilonke akufanele libe ngaphezu kwama-85dB (A).

Izinga Lokushisa Nengcindezi Yokunciphisa Ivalvu

Izici:

Isembozo se-valve samukela isakhiwo sokuzivala noma uhlobo lwe-flange, uhlobo lwekheji i-sleeve plunger valve core, uphawu lwekhoni yesihlalo esisodwa, kanye nezinga eliphezulu lokuvuza.Indawo yokuvala ipakishwe nge-carbide enosimende, futhi ingaphakathi lifafazwa ngezinto ezimelana nomthelela, nempilo ende yesevisi.Uphawu luyi-gasket yesilonda sensimbi kanye ne-graphite eguquguqukayo eqinisiwe, ukuvalwa okuthembekile.Akukho ukudlidliza.

Izicelo:

Isetshenziselwa ukulawula ukugeleza kwamanzi, ngokuvaleka okuthembekile, izinga lokuvuza eliphezulu kanye nempilo ende yesevisi.I-bypass yokuhlinzeka ngamanzi, i-spray des superheating system.

• Ingcindezi Yokuzisholo: P5450V-P57200V

• Ubukhulu bokuzisholo: DN50~DN300

• Ibanga Lokulungisa: 20:1-100:1

• Izinto Ezibalulekile: WCB, WC6, ZG20CrMo, 12Cr1MoV

• Izinga Lokushisa Lokusebenza: -29℃~570℃

• Abalamuli Abasebenzayo: Umhwamuko

• Imodi yokuxhuma: I-Flange, i-Welding

•Imodi yokudlulisa: Ugesi, I-pneumatic

I-High Temperature &Ivaluvu Yokunciphisa Ukucindezela

Izici:

I-valve yamukela uhlobo lwekheji ukwakheka kwe-porous, ngokulungiswa okuhle, akukho msindo futhi akukho vibration.Abangaphakathi bangakwazi ukusebenzisa isiteji esisodwa noma i-multi-stage throttling, esebenza kuzimo zokusebenza ezihlukene ezinengcindezi ephezulu.Ukunciphisa ingcindezi kuqedwa ku-valve eyodwa.Uma ucabangela izimo zokushisa eziphakeme, ukulungiswa kwangaphakathi nokuxhumana kunengqondo, futhi ukusebenza kuyavumelana nezimo.Isembozo se-valve siklanyelwe njengesembozo sokuzilungisa sokuzivala, esilungele izimo zokusebenza zokushisa okuphezulu kanye nemidiya yokucindezela okukhulu.Indawo yokuvala isihlalo se-valve igcwele i-carbide enosimende, futhi ingaphezulu le-core yamahhala lifafazwa nge-carbide enosimende, ekwazi ukumelana nokuguguleka futhi enempilo ende yesevisi.Indawo yokuvala i-valve yesihlalo esisodwa, ukuvala okuthembekile, ukuvuza okuncane futhi kuhle ekuzihlanzeni.

Izicelo:

Ukulawulwa kokugeleza nokucindezela kwe-steam turbine bypass kanye ne-overheated steam bypass.Ukulawula isitimu kanye nokufudumala kwamapayipi omshini wokuphehla umsi obhayela.Ukulawulwa komfutho wesitimu ophezulu wepayipi lesitimu esifudumele nesinomfutho ophezulu.

Ivalvu Yesistimu enengcindezi ephezulu

Izici:

I-valve yokungena isetshenziswa kanye ne-valve yokuhlola.Ngemuva kokuthi i-heater ephezulu igcwele amanzi, ukucindezela kwamanzi kuyanda ngokuqhubekayo.Lapho ingcindezi ikhuphukela enanini elithile, induku ye-valve ihambela phezulu ngosizo lokucindezela okuhlukile okusebenza engxenyeni yesiqu se-valve ye-valve yokungena ukuze uvule umzila ku-heater yokucindezela okuphezulu, okuvumela amanzi ukuthi angene ku-high-pressure. ihitha.Ngalesi sikhathi, i-heater enengcindezi ephezulu iyasetshenziswa.Lapho isistimu yepayipi ye-heater enomfutho ophezulu wegazi iphuka ngengozi, futhi izinga lamanzi ku-heater yokucindezela okuphezulu lidlula inani elivumelekile, isignali yezinga lamanzi ivula i-valve esheshayo yokuvula nokuvala ngomshini kagesi, i-condensate ingena ku-piston. isilinda ngenhla kwe-valve yokungena, icindezela phansi i-piston, iphushela i-relay elawulayo phansi, ivale i-inlet ye-heater enomfutho ophezulu, ivule i-bypass, kanye nokushisa komfutho ophezulu Idivayisi iyayeka ukusebenza, futhi sonke isikhathi sesenzo siyimizuzwana emi-2.

• Okujwayelekile: NB/T 47044, ASME B16.34,JB/T 3595

• Ingcindezi Yokuzisholo: PN16-PN420(CLASS900-CLASS2500)

• Ubukhulu Bamagama: DN100~DN350(4”-14”)

• Izinto Ezibalulekile: 1.WCB, ZG20CrMo, Cr5Mo, ZG20CrMoV

2.25#, 12Cr1MoV

3.ASTM A216 WCB, ASTM A217 WC6, , ASTM A217 WC9

4.ASTM A105, ASTM A182 F11, ASTM A182 F22

• Izinga Lokushisa Lokusebenza: 1. WCB: -29℃~425℃

2. Insimbi yengxubevange: -29℃~540℃, -29℃~570℃

• Abalamuli Abasebenzayo: Amanzi, I-Steam

• Imodi yokuxhuma: Ukushisela

• Imodi Yokudlulisa: Imanuwali, Ugesi, I-Hydraulic

I-Hydrostatic Testing Valve

Izici:

Ifakwe ku-outlet ye-overheater ye-boiler kanye namapayipi esitimu angenisayo naphumayo e-reheater njengendawo yodwa ngesikhathi sokuhlolwa kwe-hydrostatic.Ngemuva kokucindezela kwamanzi, susa ipuleti lokuvimbela langaphakathi njengepayipi.Ipuleti elingenalutho lingafakwa futhi ngesikhathi sokuhlolwa okulandelayo kwe-hydrostatic.

Izicelo:

1. I-pressure self tightening sealing structure iyamukelwa, futhi amapayipi egatsha emikhawulweni yomibili ashiselwe.

2. I-flat O-ring seal iyamukelwa, futhi isihlalo se-valve senziwa ngensimbi engagqwali ngokufaka i-welding.

3. Ipuleti elingenalutho kufanele lifakwe ngesikhathi sokuhlolwa kwe-hydrostatic, futhi likhishwe ngemva kokuhlolwa kwe-hydrostatic.Ukuhlolwa okuningi kwe-hydrostatic kungenziwa.• Okujwayelekile: JB/T 12002,NB/T 47044 ASME B16.34

• Ingcindezi Yokuzisholo: PN16-PN420(CLASS150-CLASS2500), P54I-100V-P57200V

• Ubukhulu Bamagama: DN100~DN1000(4”-48”)

• Izinto Ezibalulekile: 1.WCB, ZG20CrMo, Cr5Mo, ZG20CrMoV, ZG15Cr1MoV

2.25#, 12Cr1MoV

3.ASTM A216 WCB, ASTM A217 WC6, , ASTM A217 WC9, ASTM A217 C12A

4.ASTM A105, ASTM A182 F11, ASTM A182 F22, ASTM A182 F91, A182 F92

• Izinga Lokushisa Lokusebenza: 1. WCB: -29℃~425℃

2. Insimbi yengxubevange: -29℃~540℃, -29℃~570℃

3. F91: -29℃~610℃

• Abalamuli Abasebenzayo: Amanzi, I-Steam

• Imodi yokuxhuma: Ukushisela

• Imodi yokudlulisa: /

Isibonisi somkhiqizo