Amavalvu Ensimbi Engazweli Ukucindezela Okuphezulu Okuphakeme Kwezinga lokushisa

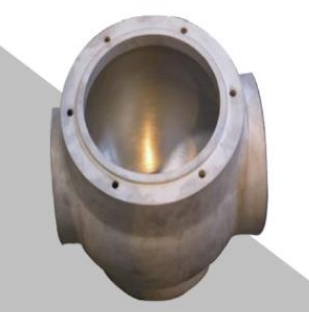

Kukhona uchungechunge oluhambisanayo lokulungiswa kwensimbi efojiwe yevalvu yesango, i-globe valve kanye ne-ball valve.I-Die Forging isetshenziselwa i-DN15-DN80, futhi ukufoja kwamahhala kusetshenziselwa ≥ DN80.I-multidirectional die forging ngesikhathi esisodwa (ubuchwepheshe bokukhiqiza isiliva obungenalutho) busetshenziswa kancane kancane emikhiqizweni ephezulu.

Izici

I-1.Finite element analysis isize umklamo wokuthuthukisa amandla nesisindo somkhiqizo.

2.Ibhonethi yokushisela, ibhonethi eboshiwe kanye nebhonethi yokuzivala ngomfutho inganikezwa ngokwezidingo zamakhasimende.

3.Ngokuvumelana nesidingo samakhasimende, singahlinzeka ngemikhiqizo yokubumba ye-die-diameter multi direction die.

I-4.Ingakwazi ukumboza wonke ama-valve ochungechunge lwensimbi yenkampani, okuhlanganisa uhlobo lwe-valve, ingcindezi, ububanzi kanye nezinto ezibonakalayo, imodi yokuxhuma kanye nemodi yokudlulisela.

I-Multi direction die forging ibhekisela ekubunjweni okunesimo esiyinkimbinkimbi, ngaphandle kwe-burr, igatsha elincane eliningi noma elinezingqimba, ezitholakala ngokusebenzisa ukufa okuhlangene, ukufudumeza kanye nokushaywa komshini wokunyathelisa kanye.Ngaphezu kwalokho, kunesidingo esikhulu kakhulu se-tonnage ye-forging press.Esikhathini esidlule, ngenxa yobukhulu bomzimba omkhulu wokulungisa ububanzi, ungenziwa kuphela ngokuhlukanisa isiliva bese uhlanganiswa futhi ushiselwe ndawonye.Uma kusetshenziswa i-multi-directional die forging, akukona nje kuphela ukuthi ukubunjwa kungenziwa ngokuqondile ekushiseni okukodwa, kodwa futhi i-cavity yangaphakathi ingahlanganiswa ndawonye, ithuthukise kakhulu amandla kanye nobuhle bendawo engenalutho ekuqondeni kwe-fiber, futhi kunciphise izindleko zomkhiqizo. .

Umehluko wenqubo phakathi kwe-valve efojiwe kanye ne-valve ephonsiwe

Ngokusakazwa kwe-valve nokufaka i-valve, inqubo ngayinye inezinzuzo zayo.Amanye amaphrojekthi akhetha indlela eyodwa kunenye.Futhi enye ifaneleka kakhulu kwabanye abantu.Ngezansi sibala umehluko omkhulu phakathi kokulingisa nokufoja:

1. Umehluko wamandla:

Izinto zokulingisa zinamandla aphansi ngoba zithelwa emgodini ovumela izinto ukuthi zakheke ngokukhululeka.

Izinto zomgunyathi zinamandla.Ngenxa yokuthi banesakhiwo sokusanhlamvu esichazwe kahle, ukucindezela ngamandla kwandisa amandla abo omshini.

2. Ifanele izimo ezingenalutho

Ukusakaza ngokuvamile kukhethwa ekukhiqizeni izinto eziqukethe izikhala ezingenalutho noma izimbotshana.

I-Forging ayifaki izimbotshana kanye ne-porosity ekwakhiweni kwayo.

3. Ukufana kuhlukile:

Izinto zokusakaza azifani ngaso sonke isikhathi.

Izinto ezifojiwe zingenziwa zibe yisimo esingaguquki futhi zigcine ukuhambisana kwesakhiwo.

4. Umkhawulo kasayizi:

Ukusakaza akunayo imikhawulo yosayizi noma umumo.Ngoba zonke izinto zokwakha zizoncibilika ngaphambi kokwakhiwa.

Izinto ezinesisindo esingafika ku-50 kg zingabunjwa.Amandla aphezulu ayadingeka uma impahla ezokwenziwa inesisindo esingaphezu kwama-50 kg.Kulokhu, ukulingisa kungaba enye indlela.

5. Ukuxakeka

Ukulingisa kungaveza amaphethini nezimo eziyinkimbinkimbi.I-Forging igxile kakhulu ekukhiqizeni izinto ezifanayo nezilula.

6. Izindleko ezihlukene:

Ukusakaza kusebenzisa okokusebenza okungabizi kakhulu.Imishini esetshenziselwa ukubumba, efana nokufa kwemboni esindayo, ibiza kakhulu.

Leli yiphepha locwaningo lapho abacwaningi baseNyuvesi yaseToledo beqhathanisa khona umehluko phakathi komkhiqizo owodwa okhiqizwa ngezindlela ezimbili.Iziphetho ezilandelayo zibalwe:

Amandla okuqina we-forging aphakeme ngo-26% kunalawo okulingisa.

Amandla okukhathala kwama-forging aphezulu ngo-37% kunalawo okulingisa.

Amandla okukhiqiza ensimbi ensimbi angama-66% kuphela ensimbi ekhandiwe.

Ama-forging abe nokwehliswa ngo-58% endaweni lapho edonswa ehluleka.Indawo yokulingisa yehliswe ngo-6%.