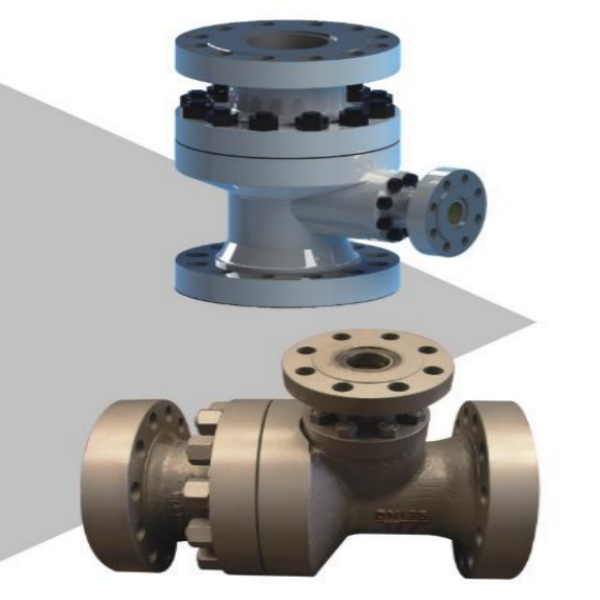

High Quality Steel Casting Power Station Check Valve

Features

1. In accordance with NB/T 47044 and ASME B16.34

2. The tension in the mesh body use the pressure sealing structure(WOOD CLOSURE), and the higher wide body inner cavity pressure the better.

3. The sealing surface of wide seat and board is made of cemented carbide surfacing or sub item welding, with high temperature resistance, abrasion resistance and scratch resistance.

• Standard: 7*84: NB/T 47044, ASME B16.34. JB/T 3595. DL/T 923

• Nominal Pressure: PN160-PN630 (CLASS900- CLASS3500) , P54100V, P54140V, P54170V, P57100V, P57140V, P57170V

• Nominal Dimension: DN50~DN350 (2”-14”)

• Main Material:

1.WCB, ZG20CrMo, Cr5Mo, ZG20CrMoV, ZG15Cr1MoV

2. 25#, 12Cr1MoV

3. ASTM A216 WCB, ASTM A217 WC6, ASTM A217 WC9, ASTM A217 C12A

4. ASSTM A105, ASTM A182 F11, ASTM A182 F22,ASTM A182 F91, ASTM A192 F92

• Operating Temperature:

1. Carbon steel: - 29℃~425℃

2. Alloy steel: - 29℃~540℃, - 29℃~570℃

3. F91:-29℃~610℃

• Applicable Intermediaries: Water, Steam, etc

• Connection Mode: Welding

• Transmission Mode: Automatic

No-load Running Check Valve

Features

It is a special quick closing valve for protecting the steam turbine generator unit. It is designed to prevent the pressure in the steam turbine from suddenly decreasing when the steam turbine unit suddenly loses load, and the steam in the extraction pipe and various heaters from flowing back into the steam turbine, causing the steam turbine blades that rotate at a high speed of more than 3000 revolutions per minute to suddenly run in reverse, thus causing a disgusting accident that the steam turbine blades are broken and the steam turbine generator is damaged, And prevent water hammer accident caused by leakage of the pipe pool of the heater system and water entering the turbine from the extraction pipe. In case of the above conditions, the valve can be closed quickly within 0.5s.

Applications:

1. The pneumatic stop callback is to push the piston in the air red through compressed air, the piston pushes the shift fork, and the shift fork drives the rocker shaft to rotate to open the valve. The valve is closed by pushing the spring grid piston back to cut off the air supply through electromagnetic adjustment.

2. The sealing surface of net candy and ridge base is made of the latest surfacing material, which has strong wear resistance and scratch resistance.

3. High performance new packing, reliable sealing, convenient and flexible operation.

• Standard: GB/T 29462

• Nominal Pressure: PN64-PN630(CLASS300-CLASS3500)

• Nominal Dimension: DN50~DN1200(2”-48”)

• Main Material: 1.WCB

2.ZG20CrMo, ZG15Cr1Mo1V

3.ASTM A216 WCB

4.ASTM A217 WC6, ASTM A217 WC9

• Operating Temperature: 1. WCB: -29℃~425℃

2.Alloy Steel: -29℃~540℃, -29℃~570℃

• Applicable Intermediaries: Water, Steam

• Connection Mode: Flange, Welding

• Transmission Mode: Pneumatic, Hydraulic

Nickel Base Alloy High Pressure& Temperature Check Valve

Features:

In order to ensure the high requirements for the tightness, reliability and safety of the screen door, the valve body is made of nickel base alloy as a whole, or fabricated and welded. The sealing surface of the valve door is welded with hard alloy to enhance its wear resistance and scratch resistance, and improve the service life of the sealing surface. The middle chamber of the wide door adopts a self sealing structure, which is conducive to high-pressure sealing. The higher the pressure, the better the sealing.

Application:

This product is suitable for high temperature, high pressure and corrosive occasions in petrochemical and oil refining industries.

• Product Standard: GB/T 12224, ASME B16.34

• Nominal Pressure: PN100~PN420 (CLASS600~CLASS2500)

• Nominal Dimension: DN25~DN200 (1”~8”)

• Main Material: Nickel Base Alloy

• Operating Temperature: - 29℃~500℃

• Applicable Intermediaries: Corrosive media such as high sulfur, high acid, etc.

• Connection Mode: Flange, Welding

• Transmission Mode: Electric

Product Display