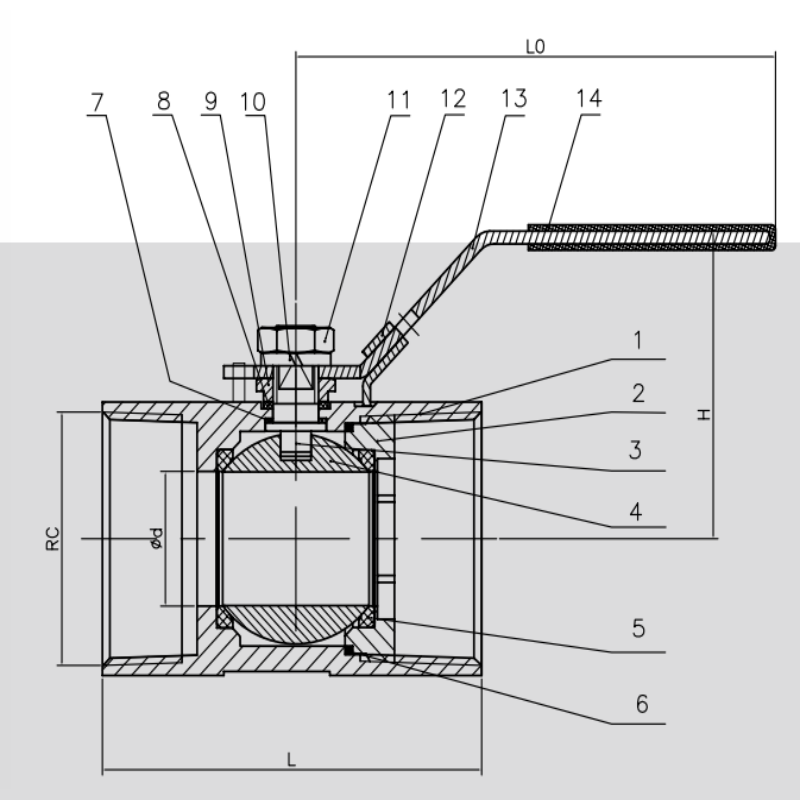

Stainless Steel Precision Casting/Investment Casting ONE-PIECE

Model 1

Description

◎ Reduced bore

◎Threaded ends: G* NPT, BSPT, BST, DIN259/2999 JIS130202/1302203 Internal entry blow-out proof stem

◎ Material: CF8M CF8 CF3M WCB 304 316 1.4408 etc

◎ Pressure rating: 1000PSI WOG / 1.6~64Mpa

◎ Lever handle

Specifications

Type 1:

|

DN |

8 |

10 |

15 |

20 |

25 |

32 |

40 |

50 |

|

RC |

1/4 |

3/8 |

1/2 |

3/4 |

1 |

11//4 |

11//2 |

2 |

|

Φd |

5 |

7 |

9.2 |

12.6 |

16 |

20 |

25 |

32 |

|

L |

39.4 |

43.7 |

57 |

58.5 |

71 |

78 |

82.5 |

100 |

|

LO |

67 |

67 |

93 |

93 |

101 |

101 |

125 |

125 |

|

H |

29.9 |

31.5 |

39.37 |

44 |

54 |

59 |

67.5 |

73.5 |

Type 2:

|

DN |

8 |

10 |

15 |

20 |

25 |

32 |

40 |

50 |

|

RC |

1/4 |

3/8 |

1/2 |

3/4 |

1 |

11//4 |

11//2 |

2 |

|

Φd |

5 |

7 |

9.2 |

12.6 |

16 |

20 |

25 |

32 |

|

L |

46.5 |

49.5 |

59 |

64 |

75 |

83 |

90.5 |

108 |

|

LO |

67 |

67 |

93 |

93 |

101 |

101 |

125 |

125 |

|

H |

29.9 |

31.5 |

39.37 |

44 |

54 |

59 |

67.5 |

73.5 |

|

Material List |

||||

|

No. |

Drawing No. |

Name |

Material |

QTY |

|

1 |

Vl-T |

Body |

CF8M |

1 |

|

2 |

Vl-G |

Cap |

CF8M |

1 |

|

3 |

Vl-FG |

Stem |

316 |

1 |

|

4 |

Vl-Q |

Ball |

CF8M |

1 |

|

5 |

Vl-Z |

Seat |

PTFE+3%GF |

2 |

|

6 |

Vl-VIF |

Gasket |

PTFE |

1 |

|

7 |

Vl-ZTD |

Thrust washer |

PTFE |

1 |

|

8 |

Vl-TL |

Stem packing |

PTFE |

1 |

|

9 |

Vl-JLM |

Nut |

304 |

1 |

|

10 |

GB93-87 |

Spring washer |

304 |

1 |

|

11 |

GB6172-86 |

Nut |

304 |

1 |

|

12 |

Vl-XS |

Stopper |

304 |

1 |

|

13 |

Vl-BS |

Handle |

304 |

1 |

|

14 |

Vl-BT |

Handle sleeve |

Rubber |

1 |

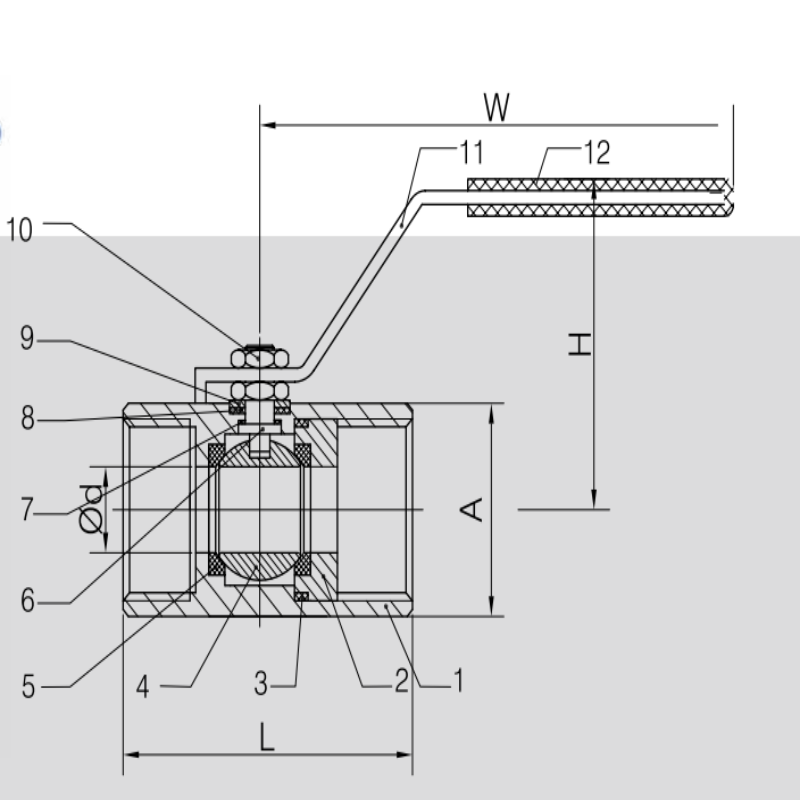

Model 2

◎Reduced bore

◎Threaded ends:ANSI B2.1,BS21,D1,1259/2999

◎.Test.:API598

◎.Pressure rating:2000PSI

◎.Shell test:.2000Mpa.

◎.Pressure.test:.0.6~0.8Mpa.

◎.Dimension:.DN8-DN50(1/4"~2")

Material List

|

No. |

Name |

Material |

|

1 |

Body |

Carbon Steel |

|

2 |

Cap |

Carbon Steel |

|

3 |

Gasket |

PTFE |

|

4 |

Ball |

316 |

|

5 |

Seat |

PTFE |

|

6 |

Stem |

316 |

|

7 |

Thrust washer |

PTFE |

|

8 |

Stem packing |

PTFE |

|

9 |

Gland |

316 |

|

10 |

Nut |

304 |

|

11 |

Handle |

304 |

|

12 |

Handle sleeve |

PLASTIC |

Dimension

|

Size |

A |

Φd |

L |

H |

W |

NM |

KGS |

|

DN8 |

20 |

4.5 |

43 |

35 |

73 |

4 |

0.11 |

|

DN10 |

25 |

7 |

45 |

38 |

73 |

4 |

0.17 |

|

DN15 |

30 |

9 |

62 |

50 |

115 |

6 |

0.33 |

|

DN20 |

36 |

12.5 |

70 |

58 |

115 |

6 |

0.48 |

|

DN25 |

41 |

15 |

85.5 |

62 |

129 |

8 |

0.70 |

|

DN32 |

53 |

20 |

94 |

64 |

129 |

10 |

1.32 |

|

DN40 |

60 |

25 |

101 |

72 |

150 |

14 |

1.89 |

|

DN50 |

70 |

32 |

114 |

80 |

150 |

20 |

2.31 |

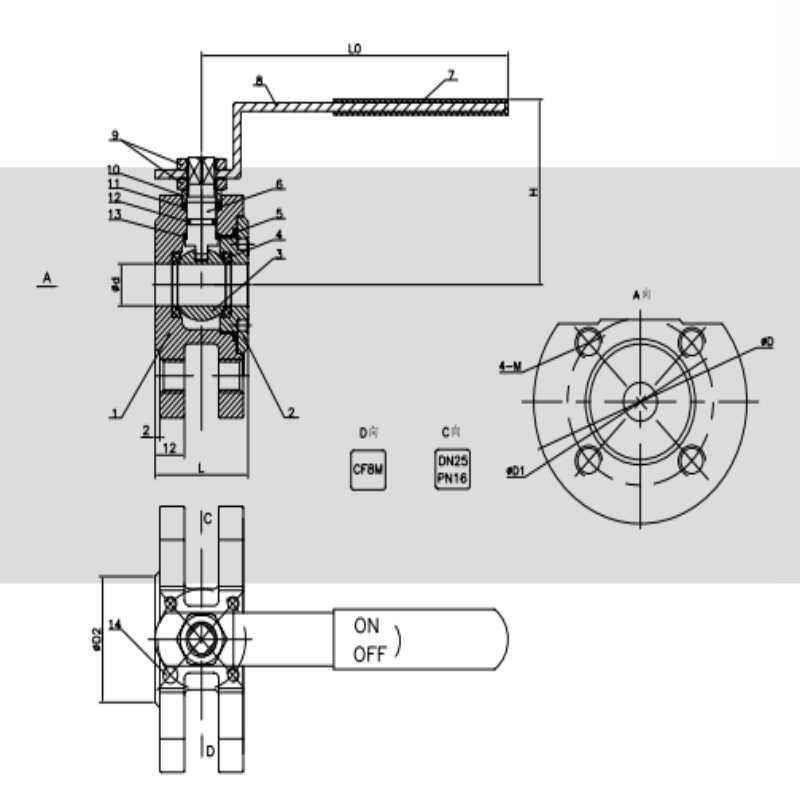

Model 3

◎ FULL BORE

◎ Flanged ends: DIN2543 ISO5752 GB12221

◎ Pressure rating: PN16

◎ Actuator mounting pad: ISO5211 Internal entry blow-out proof stem

◎ Material: 316 CF8M 1.4408 WCB 304 CF8

◎ Pressure test: API598

|

No. |

Drawing No. |

Name |

Material |

QTY |

|

1 |

VlFW-T |

Body |

CF8M |

1 |

|

2 |

VlFW-G |

Cap |

CF8M |

1 |

|

3 |

VlFW-Q |

Ball |

CF8M |

1 |

|

4 |

VlFW-Z |

Seat |

PTFE+3%GF |

2 |

|

5 |

VlFW-MF |

Gasket |

PTFE |

1 |

|

6 |

VlFW-FG |

Stem |

304 |

1 |

|

7 |

VlFW-BT |

Handle sleeve |

RUBBER |

1 |

|

8 |

VlFW-BS |

Handle |

304 |

1 |

|

9 |

VlFW-LM |

Nut |

304 |

2 |

|

10 |

VIFW-TLT |

GLAND |

304 |

1 |

|

11 |

VlFW-TL |

Stem packing |

PTFE |

1 |

|

12 |

VlFW-O |

O ring |

Viton |

1 |

|

13 |

VlFW-ZTD |

Thrust washer |

PTFE |

1 |

|

14 |

VlFW-X |

Stopper |

304 |

1 |

Application

|

Size |

Φd |

L |

H |

LO |

ΦD |

ΦD1 |

ΦD2 |

4—M |

|

1/2 |

15 |

38 |

75 |

125.2 |

95 |

65 |

45 |

M12 |

|

3/4 |

20 |

38 |

80 |

125.2 |

105 |

75 |

58 |

M12 |

|

1 |

25 |

46 |

95 |

136.2 |

115 |

85 |

68 |

M12 |

|

11//4 |

32 |

54 |

101 |

136.2 |

140 |

100 |

78 |

M16 |

|

11//2 |

38 |

63 |

122 |

204.5 |

150 |

110 |

88 |

M16 |

|

2 |

50 |

80 |

121 |

204.5 |

165 |

125 |

102 |

M16 |

|

21//2 |

65 |

100 |

142 |

250 |

185 |

145 |

122 |

4-M16 |

|

3 |

76 |

118 |

161 |

250 |

200 |

160 |

138 |

4-M16 |

|

4 |

94 |

152 |

174 |

320 |

220 |

180 |

158 |

8-M16 |

Application: Connect and cut off the medium; prevent the backflow of the medium; adjust the pressure and flow of the medium; separate, mix or distribute the medium; prevent the medium pressure from exceeding the specified value and ensure the safe operation of the pipeline or equipment.

Applicable media: steam, water, oil; chemical solution;

There are two types seals of ball valve: soft seal and hard seal;

Three connection methods: flange; thread; welding

Use temperature: -196 to 350 degrees

Operation mode: manual; pneumatic; electric; hydraulic

The difference between one-piece ball valve, two-piece ball valve and three-piece ball valve:

The screw ball valve with internal thread is divided into one-piece ball valve, two-piece ball valve and three-piece ball valve according to its structure. Understanding their characteristics and differences will help us choose the right ball valve for use.

First of all, let's first understand what is a one-piece ball valve, two-piece ball valve and three-piece ball valve by definition.

One-piece ball valve refers to a ball valve that is connected with a small-diameter internal thread and is composed of an integral one-piece valve body. The integral valve body is often used for small-sized valves.

Two-piece ball valve, also known as two-piece ball valve, refers to a valve that is connected with a small-diameter internal thread, the valve body is divided into two parts, and the buckle form is usually used.

The three-piece ball valve is connected by internal thread, and the valve body consists of three parts. It is usually used for larger and more important valves.

Their differences and characteristics can be analyzed from the following aspects:

1. Distinguish from the structure

The one-piece ball valve is one-piece, which is composed of a ball, a PTFE ring, and a lock nut. The diameter of the ball is slightly smaller than the diameter of the pipe, similar to the wide-type ball valve. Specifications, flow is relatively small.

The two-piece ball valve is composed of two parts, and the sealing effect is better than that of the one-piece ball valve. The diameter of the ball is the same as that of the pipeline, and it is easier to disassemble than the one-piece ball valve.

The three-piece ball valve is composed of three parts, the valve cover on both sides and the middle valve body. The difference between the three-piece ball valve and the two-piece ball valve and the one-piece ball valve is that it is easy to disassemble and maintain. Stronger pressure resistance.

2. Distinguish from pressure

The pressure resistance of the three-piece ball valve is much higher than that of the one-piece and two-piece ball valves. The outer side of the main three-piece ball valve is fixed by four bolts, which plays a very good tightening role. The precision casting valve body can reach a pressure of 1000psi≈6.9MPa. Higher pressures require forged valve bodies.

3. Distinguish from an economic point of view

Because the main material of the one-piece ball valve is less than that of the other two types, the price is favorable, and it is the same as the wide-type ball valve. The price of the two-piece ball valve is higher than that of the one-piece type. The three-piece type is composed of three parts because of higher pressure resistance. The material is higher than the other two types. The price is higher than the two-piece and one-piece ball valves.

Product Display