Valves

-

Pipe Discharge Breathing Valve

It can avoid the loss of the tank due to overpressure or negative pressure, and can recover the “breathing” of the tank evaporation.

-

ANSI Check Valve

The function of this lifting check valve is to allow the medium to flow in one direction only, and to stop the flow in the opposite direction. Usually, the valve works automatically. Under the action of fluid pressure flowing in one direction, the valve clack opens. When the fluid flows in the opposite direction, the adjusting tank acts on the adjusting seat by the fluid pressure and the weight of the adjusting flap to cut off the flow.

-

Lined Diaphragm H44 Check Valve

A lined diaphragm H44 check valve is a type of valve that is commonly used in industrial settings. It is made up of a diaphragm, which is a flexible material that separates the valve body from the flow medium, and a valve seat that controls the flow of fluid with full bore and no flow resistance. The valve is designed to allow fluid to flow in one direction only and prevent backflow.

-

ANSI Soft Sealing Ball Valve-Top Entry Fixed Ball Valve

The wide seat assembly adopts adjusting nuts, which truly realizes online maintenance and is simple to disassemble.

Ball valves are commonly used in various industries due to their reliable performance and ease of use. Among the different types of ball valves available, the ANSI soft sealing ball valve-top entry fixed ball valve is a popular choice for its superior sealing and durability.

-

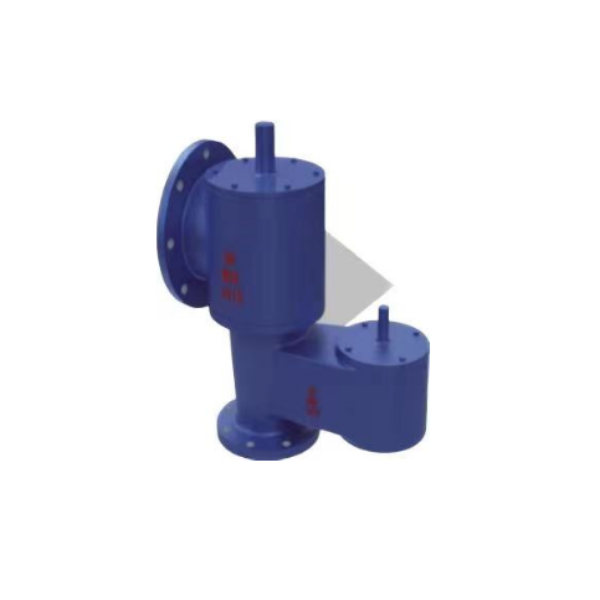

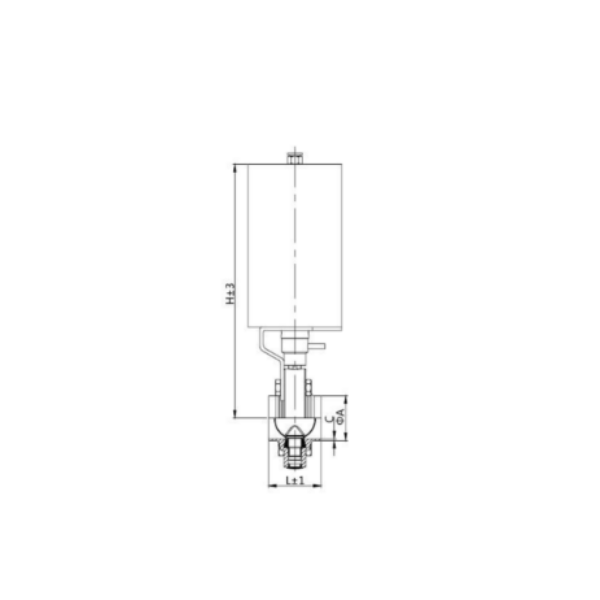

Atmospheric Discharge Breathing Valve

It can avoid the loss of the tank due to overpressure or negative pressure, and can recover the “breathing” of the tank evaporation.

-

Sanitary Pneumatic Welding Butterfly Valve

Sanitary pneumatic welding butterfly valves are essential components in many industrial applications. They are commonly used to regulate the flow of fluids, gases, and other materials in piping systems. These valves are designed to provide a high level of reliability, durability, and safety in various environments, including food and beverage processing, pharmaceuticals, and chemical industries.

-

Forged High Pressure High Temperature Resistant Steel Valves

Multi direction die forging refers to the forging with complex shape, without burr, small multi branch or with cavity, which is obtained by using combined die, once heating and once stroke of the press. Moreover, there is a very high requirement for the tonnage of forging press. In the past, due to the large size of the large diameter adjusting body, it can only be made by dividing silver and then assembled and welded together. If multi-directional die forging is used, not only the shape can be directly forged in one heat, but also the inner cavity can be forged together, greatly improving the strength and aesthetics of the blank in the fiber direction, and reducing the product cost.

-

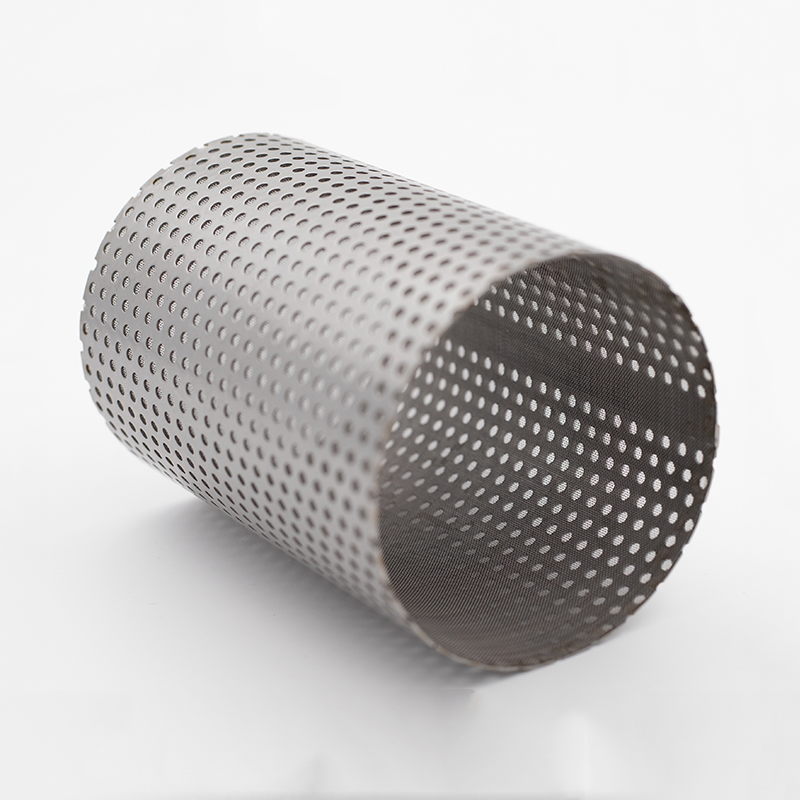

Stainless Steel Precision Casting/Investment Casting Y Strainer

The Y Strainer is used to filter and intercept the sundries in the pipeline. It can be used with other valve sleeves. It can also be used alone in the cold and hot circulating water system, the pipeline of compressed air, steam, oil and other media. . The intercepted debris is stored in the filter cartridge of the Y-Strainer, which needs to be cleaned regularly and irregularly. The filter screen can be used repeatedly, and the material of the filter screen is stainless steel.

-

Stainless Steel Precision Casting/Investment Casting TWO-PIECE Threaded Ball Valve

Two-piece ball valve is same type of gate valve, the difference is that its closing part is a ball, and the ball rotates around the center line of the valve body to control the valve opening or closing. 2pc ball valve is mainly used to cut off, distribute and change the flow direction of the medium in the pipeline.

-

Stainless Steel Precision Casting/investment Casting Globe Valve

In the open state, there is no longer any contact between the valve seat and the disc seal, so there is less mechanical wear on the sealing surface. Since the seat and disc of most globe valves are easier to repair or replace the seals without removing the entire valve from the pipeline, it is suitable for the occasion where the valve and the pipeline are welded together. When the medium passes through this type of valve, the flow direction is changed, so the flow resistance of the globe valve is higher than that of other valves.

-

Corrosion-Resistant Acid And Alkali-Resistant Cast Steel Pipeline Purging Valve

After the installation of the purging process pipe system, air purging or steam purging can be used according to the service conditions of the working medium and the dirt degree of the internal surface of the pipe. The large compressor of the production unit or the large container in the unit can be used for intermittent air purging. The purging pressure shall not exceed the design pressure of vessels and pipelines, and the flow rate shall not be less than 20m/s. The steam purging shall be carried out with large flow of steam, and the flow rate shall not be less than 30m/s.

-

Petroleum & Petrochemical Natural Gas Globe Valve

As an extremely important globe valve, the sealing of the globe valve is to apply torque to the valve stem, and the valve stem applies pressure to the regulating handle in the axial direction to make the valve loose sealing surface closely fit with the sealing surface of the valve seat and prevent the medium from leaking along the gap between the sealing surfaces.