Makina Opangira Makonda Opangira / Kuponyera Kulondola Kwamakina a Cnc Hardware Machine

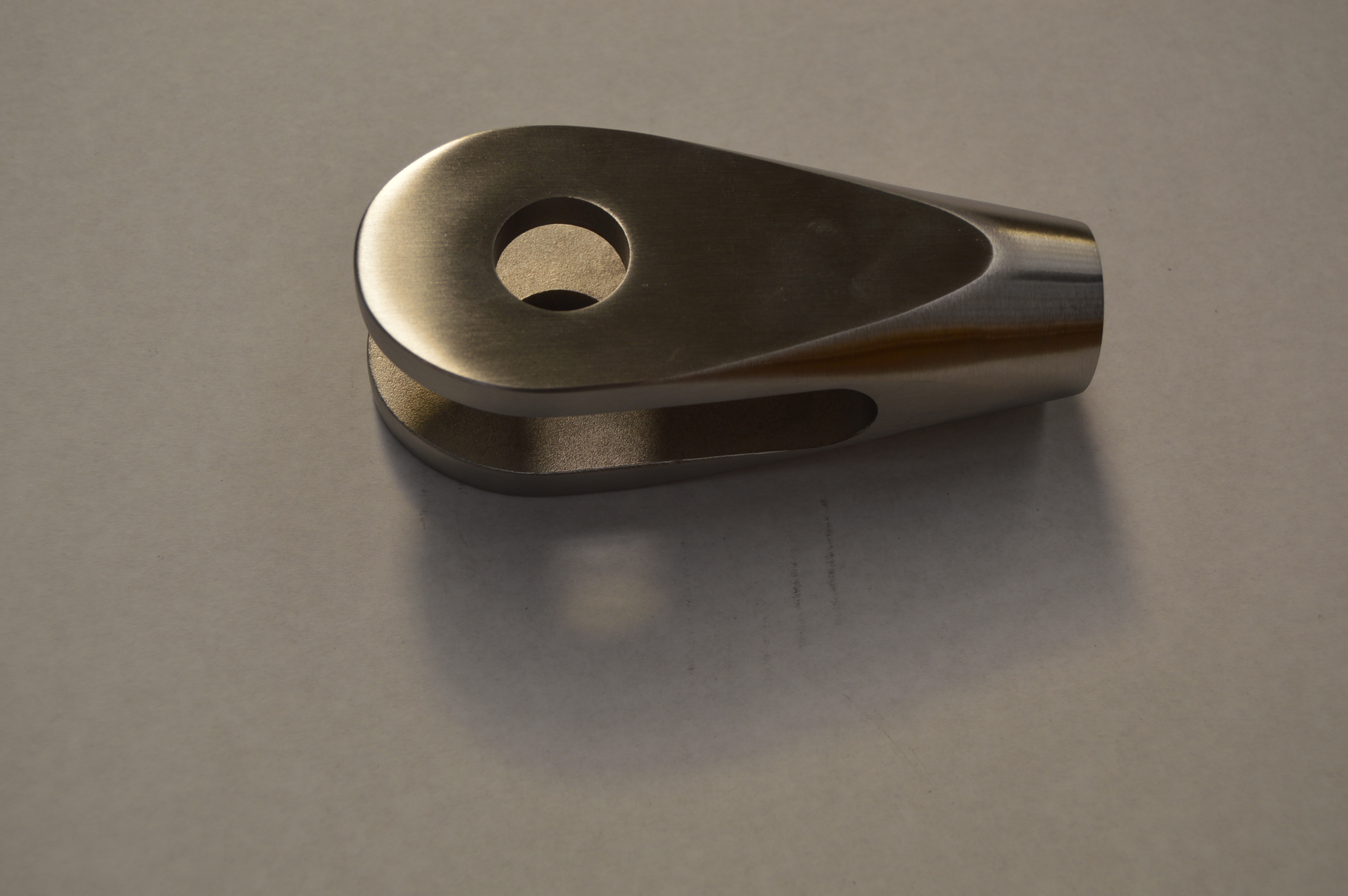

Makonda processing ndi kupanga malinga ndi zojambula

1. Zida: chitsulo chosapanga dzimbiri, chitsulo cha carbon, etc.

Processing masitepe: kudula mbali, kubowola, pogogoda, kuika, mphero, akupera, etc.

Ndikofunikira kupereka zojambula zazinthu kapena mawonekedwe enieni, miyeso, zida, kuchuluka ndi zofunikira zapadera.

2. Zida zopangira: CNC lathes, CNC lathes, lathes automatic, lathes zida zosiyanasiyana, makina obowola, etc.

3. mankhwala pamwamba: makutidwe ndi okosijeni, electroplating, quenching ndi kuumitsa mankhwala, mwatsatanetsatane kupukuta, etc.

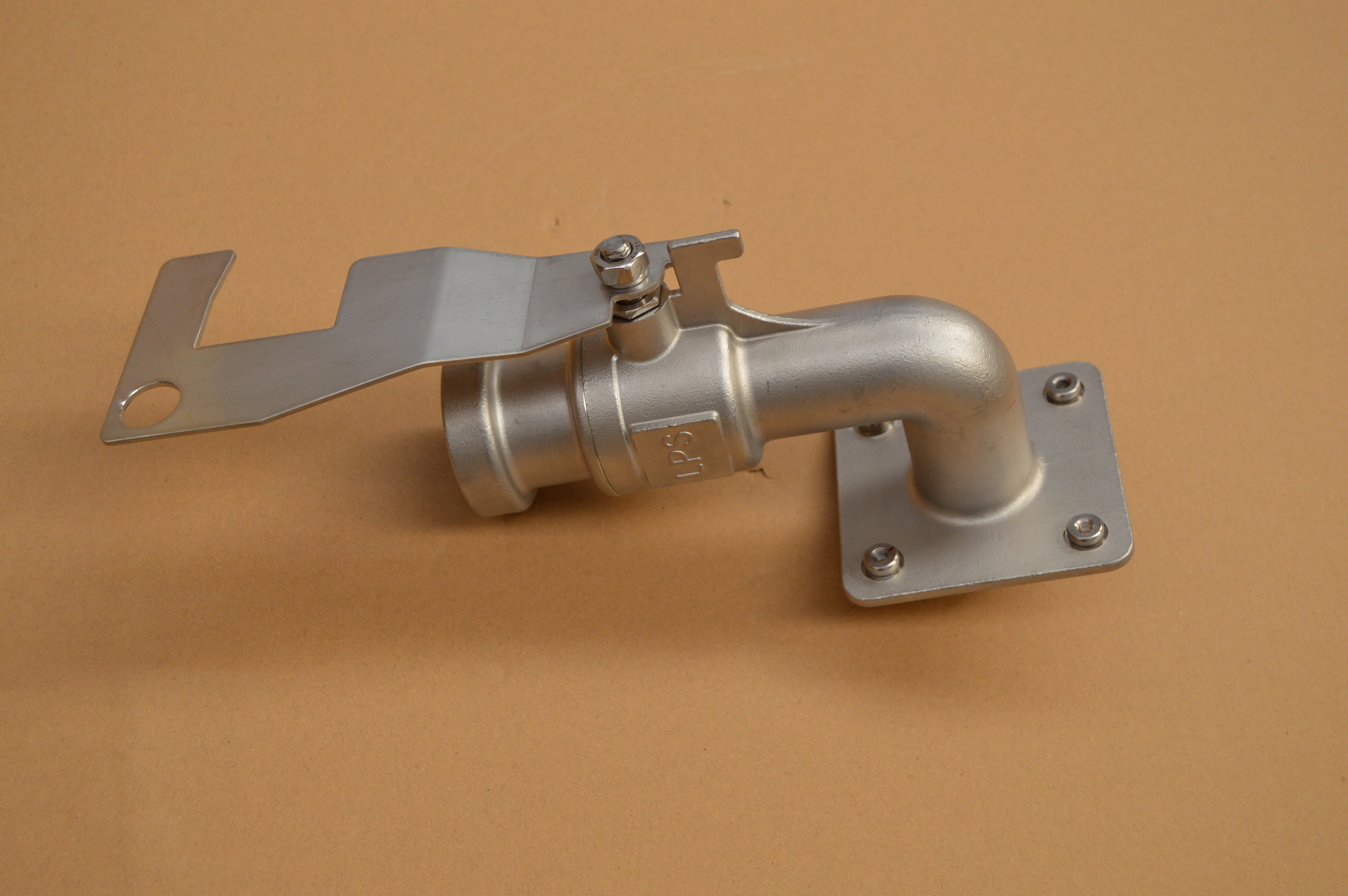

4. Titha kupereka kutembenuka kwa CNC, kutembenuza basi, kudula, kukonza, kudula ulusi, etc. kwa zida zosiyanasiyana zosagwiritsidwa ntchito, zida zogwiritsira ntchito mpweya, zipangizo zamankhwala, zamagetsi ndi zina zamagalimoto ndi zida zamakina.

Zovuta pakukonza zitsulo zosapanga dzimbiri zimaphatikizapo zinthu zotsatirazi

1. Mphamvu yodula kwambiri komanso kutentha kwakukulu

Kulimba kwa zinthuzo ndikwambiri, kupsinjika kwa tangential ndi kwakukulu ndipo kupindika kwa pulasitiki kumakhala kwakukulu pakudula, kotero mphamvu yodulira ndi yayikulu.Komanso, matenthedwe matenthedwe a zinthu zakuthupi ndi osauka kwambiri, kuchititsa kudula kutentha kukwera, ndipo kutentha kwambiri nthawi zambiri anaikira yopapatiza ndi yaitali m'dera pafupi ndi m'mphepete, potero kufulumizitsa kuvala kwa kudula chida.

2. Kulimbikira ntchito

Chitsulo chosapanga dzimbiri cha Austenitic ndi zitsulo zosapanga dzimbiri zotentha kwambiri zimakhala ndi mawonekedwe a austenitic, ndipo zimakhala ndi chizoloŵezi chachikulu choumitsa ntchito panthawi yodula, yomwe nthawi zambiri imakhala kangapo kuposa ya carbon steel wamba.Chida chodulira chimadulidwa m'dera loumitsa ntchito, lomwe limafupikitsa moyo wa chida.

3. Zosavuta kumamatira ku mpeni

Chitsulo chosapanga dzimbiri cha austenitic ndi chitsulo chosapanga dzimbiri cha martensitic chili ndi mawonekedwe a tchipisi cholimba komanso kutentha kwambiri pakukonza.Pamene tchipisi tolimba timayenda pankhope yaanga, zinthu zomatira monga kugwirizana ndi kuwotcherera zidzachitika, zomwe zidzakhudza roughness pamwamba pa makina machined.

4. Kuvala kwachangu kwa zida

Zida zomwe tatchulazi zimakhala ndi zinthu zomwe zimakhala ndi malo osungunuka kwambiri, mapulasitiki apamwamba, komanso kutentha kwambiri, zomwe zimafulumizitsa kuvala kwa zida, kukulitsa zida pafupipafupi ndikusintha zida, zomwe zimakhudza kupanga bwino ndikuwonjezera mtengo wa zida.

Timakambirana luso processing wa mbali zosapanga dzimbiri zitsulo, kuthana ndi mavuto processing, kwambiri kusintha chida moyo wa zitsulo zosapanga dzimbiri pamene kubowola, reaming ndi wotopetsa, kuchepetsa chiwerengero cha nthawi kunola ndi kusintha zida ntchito, ndi bwino kupanga dzuwa ndi processing dzenje. quality , Kuchepetsa mphamvu ya ntchito ya ogwira ntchito ndi ndalama zopangira, ndipo akhoza kupeza zotsatira zogwira mtima.

CNC makina

Mu CNC lathe processing, kutsimikiza kwa njira yosinthira nthawi zambiri kumatsatira mfundo zotsatirazi.

① Kulondola ndi kuuma kwa pamwamba kwa chogwirira ntchito chiyenera kutsimikiziridwa.

② Pangani njira yosinthira kukhala yaifupi kwambiri, chepetsani nthawi yoyenda, ndikuwongolera magwiridwe antchito.

③ Yesetsani kufewetsa kuchuluka kwa ntchito yowerengera manambala ndikusintha kachitidwe kake.

CNC makina

CNC processing (3 zithunzi)

④ Pamapulogalamu ena omwe amatha kugwiritsidwanso ntchito, ma subroutines ayenera kugwiritsidwa ntchito

CNC Machining ali ndi zotsatirazi zabwino

①Kuchuluka kwa zida kumachepetsedwa kwambiri, ndipo zida zovuta sizifunikira pakukonza magawo omwe ali ndi mawonekedwe ovuta.Ngati mukufuna kusintha mawonekedwe ndi kukula kwa gawolo, muyenera kungosintha pulogalamu yokonza gawo, yomwe ili yoyenera pakukula kwazinthu zatsopano ndikusintha.

②Ubwino wokonza ndi wokhazikika, kulondola kwadongosolo ndikwambiri, ndipo kubwereza kubwereza ndikokwera, komwe kuli koyenera pakuwongolera ndege.

③Pankhani yamitundu yosiyanasiyana komanso yaing'ono, kupanga bwino kumakhala kwakukulu, komwe kumatha kuchepetsa nthawi yokonzekera kupanga, kusintha zida zamakina ndikuwunika njira, ndipo nthawi yodulira imachepetsedwa chifukwa chogwiritsa ntchito kuchuluka koyenera. .

④ Imatha kukonza mbiri zovuta zomwe ndizovuta kuzikonza pogwiritsa ntchito njira wamba, ngakhalenso kukonza magawo ena osawoneka.

Kuipa kwa CNC Machining ndikuti zida zamakina ndizokwera mtengo ndipo zimafunikira ogwira ntchito yokonza.

Chiwonetsero cha Zamalonda