Ọdịdị B600 GMP/SAP Valve Structure

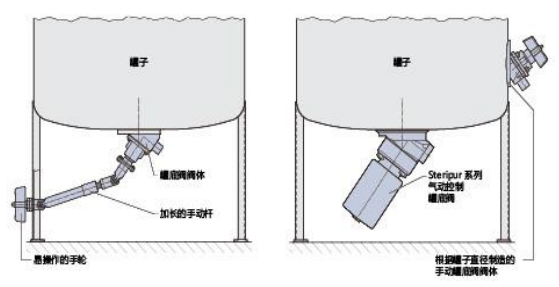

Ntuziaka maka ojiji

A na-ejikọta valvụ ala nke tank na ala nke akpa ahụ, ka o wee nweta mmetụta kachasị mma nke ịwụfu, ihicha na disinfection.Tụkwasị na nke ahụ, onye na-arụ ọrụ na-arụ ọrụ nwere ike ịgwakọta nke ọma dị ka nkà na ụzụ dị iche iche chọrọ na usoro ọrụ.Ọ dị mkpa na mkpuchi mkpuchi nke valvụ ala tank ahụ adịlarị nso dị ka o kwere mee na mgbidi ala nke tank ahụ iji nweta mmetụta efu efu efu.

Atụmatụ

——Nhazi ahụ bụ kọmpat, nke nwere ike hụ na ntinye na obere oghere.

——Ọnweghị akụkụ nwụrụ anwụ, enwere ike ịpụpụ ya ozugbo.Ejiri otu ihe eji arụ ọrụ (enweghị ihe owuwu welded).

- Kwesịrị ekwesị maka usoro CIP na SIP, enwere ike ịgba ọgwụ mgbochi na oke okpomọkụ, elu nke valvụ ahụ nwere ike ịchacha ma ọ bụ electropolished dịka ihe achọrọ, na nkenke nwere ike iru 0.25um..

——Ihe owuwu ahụ dị mma ma n’ihe gbasara ọnụego na-asọpụta na usoro chọrọ, ọ gaghị enwekwa ọgba aghara n’oge mkpofu.usoro.

——Enwere ike ịnye oghere ọkọlọtọ mba ụwa niile dị ugbu a, dị ka nkwonkwo welded, nkwonkwo mkpọgidere ma ọ bụ nkwonkwo eriri, wdg.

--The valvụ ahụ ihe bụ 1.4435/316L igwe anaghị agba nchara, n'ezie, ndị ọzọ alloys nwekwara ike iji dị ka ndị ahịa chọrọ..

——Tankị ala valvụ ahụ nwere ike iji wiil aka, isi pneumatic ma ọ bụ isi eletrik.

——A na-anabata ihe mgbanaka mgbanaka iji belata ihe isi ike nke ịgbado ọkụ n'okpuru tank.

Emecha elu elu

Ebe a na-arụ ọrụ nke ọma, nke a haziri nke ọma na ndị ọkachamara a zụrụ azụ na-enye nkwa maka nhazi dị elu nke valvụ ahụ.Enwere ike nweta ihe achọrọ iji dị iche iche site n'igweri, polishing, electropolishing ma ọ bụ electrolysis.Ngwunye elu site na 6.3m ruo 0.25m.

| ValveSurfaceFinishGrade (DIN4768Standard) | Koodu | |

| Ra ≤0.6m | Ta na-asachapụ ya n'ime na mpụta n'ụzọ igwe, a na-ejikwa cha cha enyo gbachie elu ya. | 1534 |

| Ra ≤0.6m | Electropolishing nke ime na elu elu | 1535 |

| Ra ≤0.4m | A na-asachapụ elu ime ime na mpụta nke ọma, a na-ejikwa cha cha enyo gbachie elu ya. | 1536 |

| Ra ≤0.4m | Electropolishing nke ime na elu elu | 1537 |

| Ra ≤0.25m | A na-asachapụ elu ime ime na mpụta nke ọma, a na-ejikwa cha cha enyo gbachie elu ya. | 1538 |

| Ra ≤0.25m | Electropolishing nke ime na elu elu | 1539 |

Diaphragms maka ọgwụ, nri na biotech

| Nha diaphragm | Ihe onwunwe | FDA | Ọkara mmiri | HighTeze ukwuSotuSegwu egwu |

| FPDM | 177.2600 | 90C | 150 ℃/40 nkeji | |

| PTFE/EPDM | 177.1550/21 | 90C | 150 ℃/40 nkeji | |

| EPDM | 177.2600 | 90C | 130 ℃/40 nkeji | |

| PTFE/EPDM | 177.1550/21 | 90C | 150 ℃/40 nkeji | |

| PTFE/EPDM | 177.1550/21 | 90C | 150 ℃/60 nkeji | |

| PTFE | 177.1550/21 | 90C | 160 ℃/60 nkeji | |

| EPDM | 177.2600 | 90C | 130 ℃/40 nkeji |

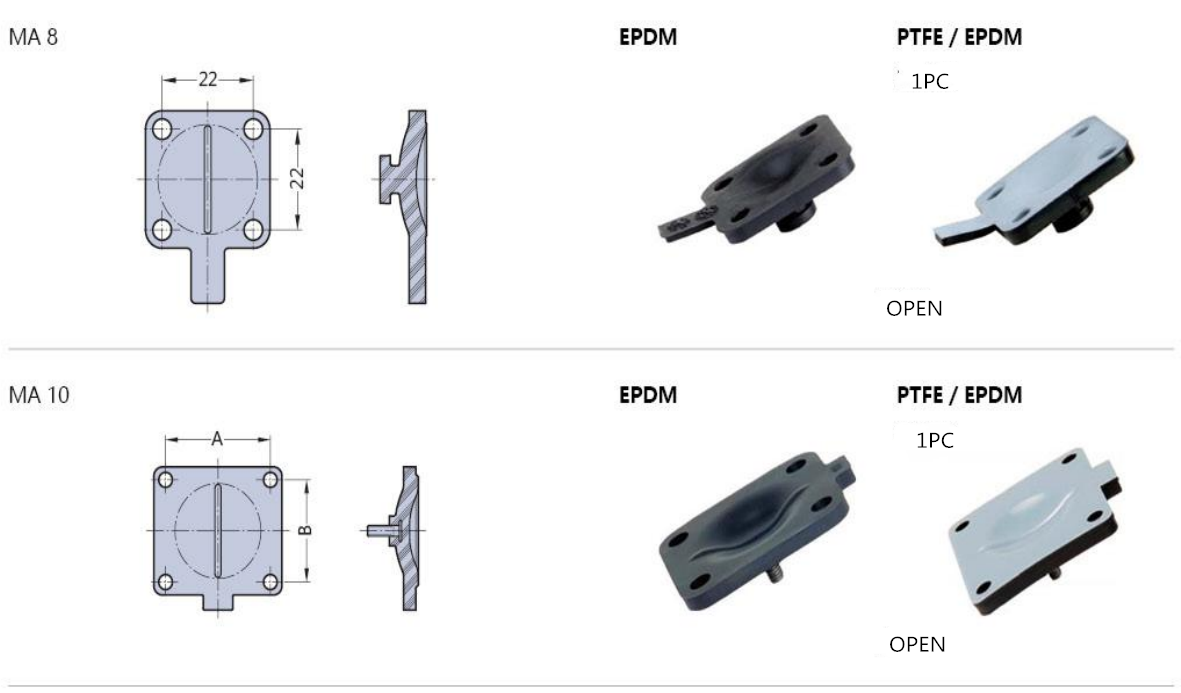

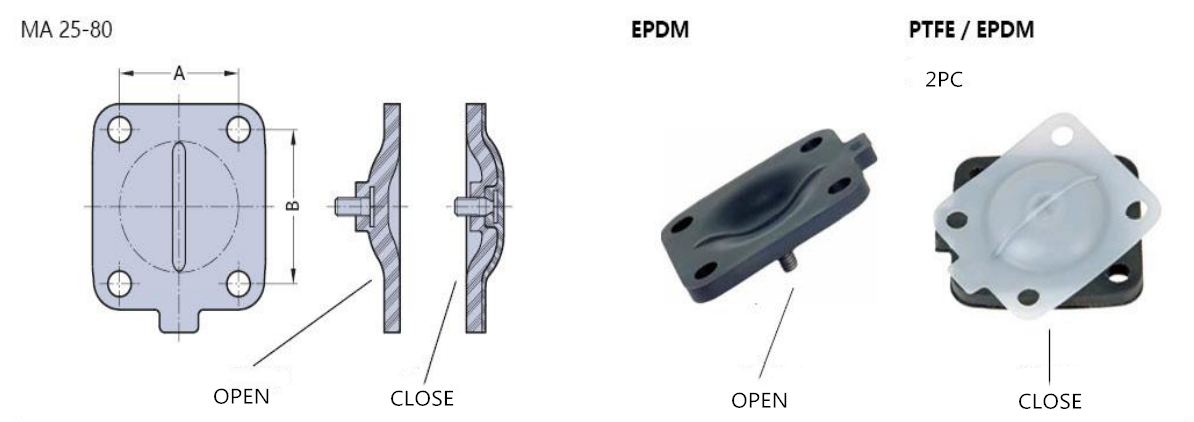

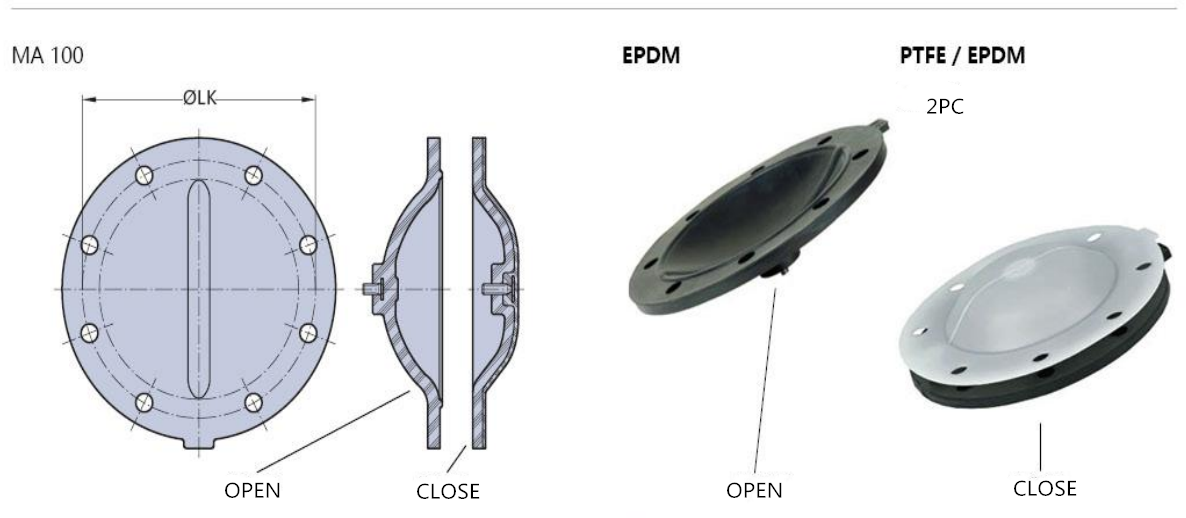

Diaphragms

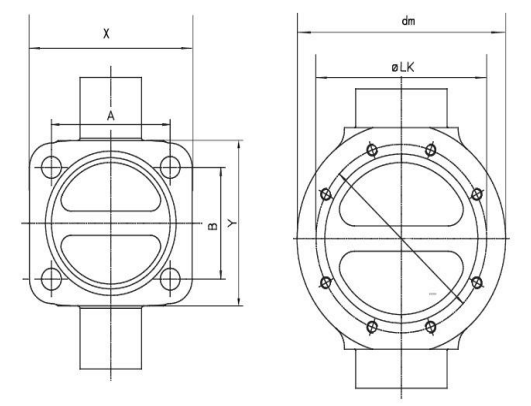

| Valve Nlereanya | MA | ISO | ASME-BPE | A | B | LK | x | y | dm | ||||

|

|

| DN(mm) | ID(mm) | Kv(m³/h) | DN(mm) | ID(mm) | Kv(m³/h) |

|

|

|

|

|

|

| 8873,8850 | 8 | 4 |

|

| 4 |

|

| 22 | 22 | - | 32 | 32 | - |

| 8 | 6 |

|

| 6 |

|

| |||||||

| 8 | 8 | 10, 3 | 2, 4 | 8 | 4, 57 | 0, 7 | |||||||

| 8 | 10 |

|

| 10 | 7, 75 | 1, 4 | |||||||

| 8 | 15 |

|

| 15 | 9, 40 | 2, 0 | |||||||

| 8873,8850 | 10 | 10 | 14,0 | 3, 9 | 10 | 7, 75 | 1, 4 | 39 | 44 | - | 50 | 55 | - |

| 10 | 15 | 18, 1 | 5, 3 | 15 | 9, 40 | 2, 2 | |||||||

| 8873,8850 | 25 | 15 | 18,1 | 11 | 15 | 9, 40 | 2, 2 | 54 | 46 | - | 74 | 68 | - |

| 25 | 20 | 23, 7 | 12, 5 | 20 | 15, 75 | 6, 8 | |||||||

| 25 | 25 | 29, 6 | 21,0 | 25 | 22, 1 | 11, 5 | |||||||

| 8873,8850 | 40 | 32 | 38, 4 | 43, 0 |

|

|

| 70 | 65 | - | 102 | 92 | - |

| 40 | 40 | 44, 3 | 50,0 | 40 | 34, 8 | 40,0 | |||||||

| 8873,8850 | 50 | 50 | 56, 3 | 64, 0 | 50 | 47, 5 | 48, 0 | 82 | 78 | - | 125 | 110 | - |

| 8873,8850 | 80 | 65 | 72, 1 | 95, 0 | 65 | 60, 2 | 85, 0 | 127 | 114 | - | 192 | 162 | - |

| 80 | 80 | 84, 3 | 127,0 | 80 | 72, 9 | 110,0 | |||||||

| 8873,8850 | 100 | 100 | 109, 7 | 205,0 | 100 | 97, 4 | 185,0 | - | - | 194 | - | - | 234 |

Diaphragms