Kubbada Qaadista Saxda ah ee Birta Aan-la-lahayn/Maalgelinta Maalgelinta

Noocyada

kubad go'an

Ku go'an kubbadda gacanta

Kubad go'an oo laba dhinac ah

Kubad go'an oo saddex geesood ah

kubbad afar geesood ah

kubbad qaloocan

kubad adag

kubad badh-go'an

sabayn kubbadda waalka

kubbad godan

Kubad qaabaysan V

L/T/kubada meelaynta iyo kubbada shaabadeynta jilicsan, iwm.

Mabda'a wareega wareega

Habka Farsamada Wax-soo-saarka

(1) Jiidista

Habkani waa hab-dhaqameed dhaqameed, kaas oo u baahan qalab dhamaystiran oo dhalaalid, shubid iyo qalab kale, iyo sidoo kale aqoon-is-weydaarsiyo waaweyn iyo shaqaale badan, maalgashi ballaaran, habab badan, hababka wax soo saarka ee adag, iyo wasakhowga deegaanka.Heerka farsamada ee shaqaaluhu waxay si toos ah u saameeyaan tayada alaabta.Dhibaatada daadinta daloolada xididada wareega ah si buuxda looma xallin karo, gunnada mashiinnada ee bannaanna waa weyn tahay qashinkana waa weyn yahay.

(2) Been abuurasho

Tani waa hab kale oo ay qaateen shirkado badan oo ka mid ah valve-ka gudaha hadda.Waxay leedahay laba hab oo farsamaynta: mid waa in la isticmaalo birta wareegsan si loo gooyo, kululeeyo oo loo been abuurtay meel bannaan oo adag oo wareegsan, ka dibna la sameeyo farsamaynta farsamada.Midda labaad waa in lagu dhejiyo saxannada birta ah ee wareegsan ee jaraa'id weyn si loo helo meel bannaan oo hemispherical ah, ka dibna lagu makiinado meel wareeg ah oo maran.Habkani waxa uu leeyahay heerka isticmaalka walxaha sare, laakiin wuxuu u baahan yahay mashiin awood sare leh.

(3) Milicso

Habka bir-wareejinta waa hab farsamaysan oo horumarsan oo leh jajab yar oo aan lahayn chips, kaas oo iska leh laan cusub oo ka shaqaynta cadaadiska.), Badbaadinta waqti badan oo farsameyn ah (1-5 daqiiqo samaynta), iyo xoogga walxaha waa la labanlaabmi karaa ka dib marka la leexiyo.Sababtoo ah aagga yar ee xiriirka u dhexeeya giraangiraha wareega iyo qaybta shaqada inta lagu jiro wareegga, walxaha birta ah waxay ku jiraan laba ama saddex-jid oo cadaadis cadaadis ah, taas oo sahlan in la qaabeeyo, iyo xiriir sare oo unug ah ayaa la heli karaa. oo leh awood yar.

Cadaadiska (ilaa 25-35Mpa), sidaas darteed, qalabku waa khafiifa miisaan, iyo wadarta awoodda loo baahan yahay waa yar tahay (in ka yar 1 / 5-1 / 4 ee saxaafadda), kaas oo loo aqoonsaday warshadaha valve shisheeye sida Habaynta goob tamarta-badbaadinta ah Qorshaha habraaca ayaa sidoo kale ku habboon habaynta qaybaha kale ee wareega ee bannaan.

Tignoolajiyada lafdhabarta ayaa si weyn loo isticmaalay oo lagu horumariyay xawaare sare wadamo badan.Tiknoolajiyada iyo qalabku waa kuwo aad u qaan-gaar ah oo deggan, iyo xakamaynta tooska ah ee isku-dhafka makaanikada, korantada iyo hydraulic waa la xaqiijiyay.

Astaamaha

-Xajmiga:l/4"-6"

-Maalgashiga Kubbada birta ah ee shubka

-Waxyaabaha kubadda CF8M CF8 CF3M

Waxaan soo saari karnaa dhammaan noocyada kubbadaha iyadoo loo eegayo shuruudaha macaamiisheena

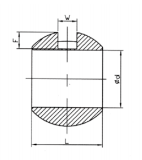

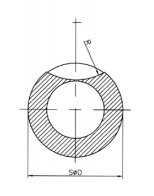

Cabirka:

| SΦD | Φd | L | W | F | R |

| 15.5 | 9.2 | 11.5 | 4 | 2.5 | 10 |

| 20.5 | 12.5 | 15.2 | 4 | 2.7 | 10 |

| 25.5 | 15 | 19.3 | 5 | 4 | 13 |

| 32 | 20 | 23.7 | 5 | 5 | 13.6 |

| 39 | 25 | 28.5 | 8 | 5.8 | 19 |

| 42.5 | 25 | 32.9 | 8 | 7 | 20 |

| 50 | 32 | 36 | 8 | 7 | 25 |

| 60 | 38 | 45 | 9.5 | 8 | 28 |

| 63 | 38 | 48.5 | 9.5 | 9 | 30 |

| 76.5 | 50 | 56 | 9.5 | 8.5 | 28 |

| 80 | 50.8 | 59.9 | 9.6 | 10 | 37.5 |

| 97 | 65 | 70.5 | 12 | 12 | 50 |

| 100 | 65 | 73.7 | 12 | 15 | 50 |

| 115 | 76 | 84.3 | 12 | 12 | 50 |

| 120 | 76 | 90 | 12 | 15 | 50 |

| 125 | 80 | 93.7 | 16 | 15 | 37.5 |

| 148 | 94 | 112 | 15 | 14 | 62.5 |

| 152 | 100 | 111.4 | 16 | 17 | 75 |

| 194 | 125 | 145 | 20 | 24 | 50 |

| 230 | 150 | 170 | 22 | 26 | 75 |

Liiska Agabka:

| Nooca | C | Si | Mn | P | S | Cr | Ni | Mo |

| CF8M | ≤ 0.08 | ≤ 1.5 | ≤ 1.5 | ≤ 0.04 | ≤ 0.04 | 18.0 ilaa 21.0 | 9.0 ilaa 12.0 | 2.0 ilaa 3.0 |

| CF8 | ≤ 0.08 | ≤ 2.0 | ≤ 1.5 | ≤ 0.04 | ≤ 0.04 | 18.0 ilaa 21.0 | 8.0 ilaa 11.0 |

|

| CF3M | ≤ 0.03 | ≤ 1.5 | ≤ 1.5 | ≤ 0.04 | ≤ 0.04 | 17.0 ilaa 21.0 | 9.0 ilaa 13.0 | 2.0 ilaa 3.0 |

Bandhiga Alaabta