I-Stainless Steel Precision Casting/Ibhola Lokusakaza Lokutshala Imali

Izinhlobo

ibhola elilungisiwe

Kulungiswe ngebhola lesibambo

Ibhola elinezinhlangothi ezimbili

Ibhola elimiswe ngezindlela ezintathu

ibhola elinezinhlangothi ezine

ibhola eligobile

ibhola eliqinile

ibhola elilinganiselwe

ibhola le-valve elintantayo

ibhola elingenalutho

Ibhola elimise okwe-V

Ibhola le-L/T/lendawo kanye nebhola le-tee elithambile, njll.

Umgomo wokuphotha indawo

Inqubo Yokukhiqiza Yezobuchwepheshe

(1) Ukulingisa

Lena indlela yokucubungula yendabuko, edinga isethi ephelele yokuncibilika, ukuthulula nezinye izinto zokusebenza, kanye nama-workshops amakhulu kanye nabasebenzi abaningi, ukutshalwa kwezimali okukhulu, izinqubo eziningi, izinqubo zokukhiqiza eziyinkimbinkimbi, kanye nokungcoliswa kwemvelo.Izinga lobuchwepheshe labasebenzi lithinta ngqo ikhwalithi yomkhiqizo.Inkinga yokuvuza kwama-capillary pores ayindilinga ayikwazi ukuxazululwa ngokuphelele, futhi isibonelelo sokusebenza esingenalutho sikhulu futhi imfucuza inkulu.

(2) Ukuqamba

Lena enye indlela esetshenziswa izinkampani eziningi zamavalvu ezifuywayo njengamanje.Inezindlela ezimbili zokucubungula: eyodwa iwukusebenzisa insimbi eyindilinga ukusika, ukushisa kanye nokwenza into engenalutho eyindilinga, bese kwenziwa ukucubungula ngomshini.Okwesibili ukubumba ipuleti eliyindilinga lensimbi engagqwali emshinini omkhulu wokunyathelisa ukuze uthole indawo engenalutho ye-hemispherical, bese umshini ingenalutho eliyindilinga elishiselwe.Le ndlela inezinga eliphezulu lokusebenzisa izinto, kodwa idinga umshini onamandla amakhulu.

(3) Ukuphotha

Indlela yokuphotha insimbi iyindlela ethuthukisiwe yokucubungula enama-chips ambalwa futhi awekho ama-chips, okuyingxenye yegatsha elisha lokucubungula ingcindezi.), igcina isikhathi esiningi sokucubungula (imizuzu engu-1-5 yokwenza), futhi amandla wezinto ezibonakalayo angaphinda aphindwe kabili ngemva kokuphotha.Ngenxa yendawo encane yokuxhumana phakathi kwesondo elijikelezayo kanye nocezu lomsebenzi ngesikhathi sokuphotha, izinto zensimbi zisesimweni sokucindezela okubili noma ezintathu, okulula ukusilimaza, futhi ukuxhumana kweyunithi ephezulu kungatholwa. ngamandla amancane.

Ukucindezeleka (kufika ku-25-35Mpa), ngakho-ke, imishini ilula ngesisindo, futhi amandla aphelele adingekayo mancane (ngaphansi kwe-1/5-1/4 yomshini wokunyathelisa), okuye kwaqashelwa imboni ye-valve yangaphandle njenge ukucutshungulwa kwe-sphere yokonga amandla Uhlelo lwenqubo nalo lufanele ukucubungula ezinye izingxenye ezizungezayo eziyize.

Ubuchwepheshe bokuphotha busetshenziswe kabanzi futhi bathuthukiswa ngesivinini esikhulu emazweni amaningi.Ubuchwepheshe nemishini kuvuthiwe kakhulu futhi kuzinzile, futhi ukulawulwa okuzenzakalelayo kokuhlanganiswa kwemishini, kagesi kanye ne-hydraulic kuyabonakala.

Izici

-Usayizi:l/4"-6"

-Investment Casting Stainless steel ibhola

-Material of the ball CF8M CF8 CF3M

-Singakwazi ukukhiqiza zonke izinhlobo zamabhola ngokuvumelana nemfuneko yamakhasimende ethu

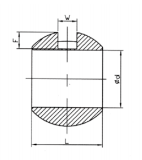

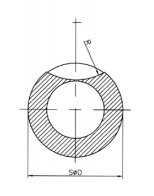

Ubukhulu:

| I-SΦD | Φd | L | W | F | R |

| 15.5 | 9.2 | 11.5 | 4 | 2.5 | 10 |

| 20.5 | 12.5 | 15.2 | 4 | 2.7 | 10 |

| 25.5 | 15 | 19.3 | 5 | 4 | 13 |

| 32 | 20 | 23.7 | 5 | 5 | 13.6 |

| 39 | 25 | 28.5 | 8 | 5.8 | 19 |

| 42.5 | 25 | 32.9 | 8 | 7 | 20 |

| 50 | 32 | 36 | 8 | 7 | 25 |

| 60 | 38 | 45 | 9.5 | 8 | 28 |

| 63 | 38 | 48.5 | 9.5 | 9 | 30 |

| 76.5 | 50 | 56 | 9.5 | 8.5 | 28 |

| 80 | 50.8 | 59.9 | 9.6 | 10 | 37.5 |

| 97 | 65 | 70.5 | 12 | 12 | 50 |

| 100 | 65 | 73.7 | 12 | 15 | 50 |

| 115 | 76 | 84.3 | 12 | 12 | 50 |

| 120 | 76 | 90 | 12 | 15 | 50 |

| 125 | 80 | 93.7 | 16 | 15 | 37.5 |

| 148 | 94 | 112 | 15 | 14 | 62.5 |

| 152 | 100 | 111.4 | 16 | 17 | 75 |

| 194 | 125 | 145 | 20 | 24 | 50 |

| 230 | 150 | 170 | 22 | 26 | 75 |

Uhlu Lwezinto:

| Uhlobo | C | Si | Mn | P | S | Cr | Ni | Mo |

| CF8M | ≤ 0.08 | ≤ 1.5 | ≤ 1.5 | ≤ 0.04 | ≤ 0.04 | 18.0 - 21.0 | 9.0 - 12.0 | 2.0 - 3.0 |

| CF8 | ≤ 0.08 | ≤ 2.0 | ≤ 1.5 | ≤ 0.04 | ≤ 0.04 | 18.0 - 21.0 | 8.0 - 11.0 |

|

| CF3M | ≤ 0.03 | ≤ 1.5 | ≤ 1.5 | ≤ 0.04 | ≤ 0.04 | 17.0 - 21.0 | 9.0 - 13.0 | 2.0 - 3.0 |

Isibonisi somkhiqizo