Stainless Steel Precision Casting / Investment Casting Ball

Mefuta

bolo e tsitsitseng

E tsitsitse ka bolo ea letsoho

Ball e tsitsitseng ea litsela tse peli

Ball e tsitsitseng ea litsela tse tharo

bolo ya maoto a mane

bolo e kobehileng

bolo e tiileng

bolo e sa fetoheng

bolo ea belofo e phaphametseng

bolo e sekoti

bolo e nang le sebopeho sa V

L/T/bolo e behang le bolo e tiisitsoeng e bonolo, joalo-joalo.

Molao-motheo oa ho bilika ha selikalikoe

Ts'ebetso ea Teknoloji ea Tlhahiso

(1) Ho lahla

Ena ke mokhoa o tloaelehileng oa ho sebetsa, o hlokang sete e feletseng ea ho qhibiliha, ho tšollela le lisebelisoa tse ling, hammoho le lithupelo tse kholoanyane le basebetsi ba eketsehileng, matsete a maholo, mekhoa e mengata, mekhoa e rarahaneng ea tlhahiso, le tšilafalo ea tikoloho.Boemo ba tekheniki ba basebetsi bo ama ka kotloloho boleng ba sehlahisoa.Bothata ba ho lutla ha li-spherical capillary pores bo ke ke ba rarolloa ka ho feletseng, 'me chelete e se nang letho ea machining e kholo le litšila tse ngata.

(2) Ho qhekella

Ena ke mokhoa o mong o amohetsoeng ke lik'hamphani tse ngata tsa li-valve tsa lapeng hajoale.E na le mekhoa e 'meli ea ts'ebetso: e' ngoe ke ho sebelisa tšepe e chitja ho seha, ho futhumatsa le ho etsa sekheo se chitja se tiileng, ebe se etsa ts'ebetso ea mochini.Ea bobeli ke ho bopa poleiti e chitja ea tšepe e sa hloekang mochining o moholo oa khatiso ho fumana sekheo se se nang letho sa hemispherical, ebe o kenya sekoti se chitja se se nang letho.Mokhoa ona o na le sekhahla se phahameng sa tšebeliso ea thepa, empa o hloka mochine o matla haholo.

(3) Ho ohla

Metal spinning method ke mokhoa o tsoetseng pele oa ho sebetsa o nang le li-chips tse seng kae mme o se na li-chips, tseo e leng tsa lekala le lecha la khatello ea khatello.), ho boloka nako e ngata ea ho sebetsa (metsotso ea 1-5 bakeng sa ho theha), 'me matla a thepa a ka imena habeli ka mor'a ho ohla.Ka lebaka la sebaka se senyenyane sa khokahano lipakeng tsa lebili la rotary le sekhechana sa mosebetsi nakong ea ho ohla, thepa ea tšepe e maemong a khatello ea maikutlo a mabeli kapa a mararo, ao ho leng bonolo ho a senya, 'me ho ka fumanoa khokahano e phahameng ea yuniti. ka matla a manyane.

Ho imeloa kelellong (ho fihlela ho 25-35Mpa), ka hona, thepa e boima ba 'mele,' me matla a feletseng a hlokahalang a nyenyane (ka tlase ho 1 / 5-1 / 4 ea mochine oa khatiso), e 'nileng ea amoheloa ke indasteri ea li-valve tsa linaheng tse ling e le ts'ebetso ea sphere e bolokang matla Morero oa ts'ebetso o boetse o loketse ho sebetsana le likarolo tse ling tse pota-potileng tse se nang letho.

Theknoloji ea ho ohla e 'nile ea sebelisoa haholo le ho ntlafatsoa ka lebelo le phahameng linaheng tse ngata.Theknoloji le lisebelisoa li hōlile haholo ebile li tsitsitse, 'me ho laola ka mokhoa o itekanetseng oa ho kopanya mechine, motlakase le hydraulic ho phethahala.

Likaroloana

-Size:l/4"-6"

- Investment Casting Stainless steel ball

-Material ea bolo CF8M CF8 CF3M

-Re ka hlahisa mefuta eohle ea libolo ho latela tlhoko ea bareki ba rona

Boemo:

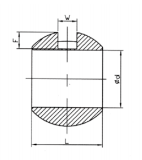

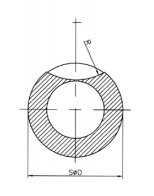

| SΦD | Φd | L | W | F | R |

| 15.5 | 9.2 | 11.5 | 4 | 2.5 | 10 |

| 20.5 | 12.5 | 15.2 | 4 | 2.7 | 10 |

| 25.5 | 15 | 19.3 | 5 | 4 | 13 |

| 32 | 20 | 23.7 | 5 | 5 | 13.6 |

| 39 | 25 | 28.5 | 8 | 5.8 | 19 |

| 42.5 | 25 | 32.9 | 8 | 7 | 20 |

| 50 | 32 | 36 | 8 | 7 | 25 |

| 60 | 38 | 45 | 9.5 | 8 | 28 |

| 63 | 38 | 48.5 | 9.5 | 9 | 30 |

| 76.5 | 50 | 56 | 9.5 | 8.5 | 28 |

| 80 | 50.8 | 59.9 | 9.6 | 10 | 37.5 |

| 97 | 65 | 70.5 | 12 | 12 | 50 |

| 100 | 65 | 73.7 | 12 | 15 | 50 |

| 115 | 76 | 84.3 | 12 | 12 | 50 |

| 120 | 76 | 90 | 12 | 15 | 50 |

| 125 | 80 | 93.7 | 16 | 15 | 37.5 |

| 148 | 94 | 112 | 15 | 14 | 62.5 |

| 152 | 100 | 111.4 | 16 | 17 | 75 |

| 194 | 125 | 145 | 20 | 24 | 50 |

| 230 | 150 | 170 | 22 | 26 | 75 |

Lethathamo la lintho tse bonahalang:

| Mofuta | C | Si | Mn | P | S | Cr | Ni | Mo |

| CF8M | ≤ 0.08 | ≤ 1.5 | ≤ 1.5 | ≤ 0.04 | ≤ 0.04 | 18.0 ho isa ho 21.0 | 9.0 ho isa ho 12.0 | 2.0 ho isa ho 3.0 |

| CF8 | ≤ 0.08 | ≤ 2.0 | ≤ 1.5 | ≤ 0.04 | ≤ 0.04 | 18.0 ho isa ho 21.0 | 8.0 ho isa ho 11.0 |

|

| CF3M | ≤ 0.03 | ≤ 1.5 | ≤ 1.5 | ≤ 0.04 | ≤ 0.04 | 17.0 ho isa ho 21.0 | 9.0 ho isa ho 13.0 | 2.0 ho isa ho 3.0 |

Pontšo ea Sehlahisoa