I-Stainless Steel Precision Casting / iBhola yoTyalo-mali

Iintlobo

ibhola esisigxina

Ilungiswe ngebhola yomqheba

Ibhola elimiyo enamacala amabini

Ibhola esisigxina eneendlela ezintathu

ibhola elineendlela ezine

ibhola egobileyo

ibhola eyomeleleyo

ibhola elimisiweyo

ibhola yevalve edadayo

ibhola engenanto

Ibhola emilise uV

L/T/ibhola yokubeka kunye nebhola ethambileyo yokutywina, njl.

Umgaqo wokujikeleza

Inkqubo yoBugcisa boMveliso

(1) Ukuphosa

Le yindlela yokucubungula yemveli, efuna isethi epheleleyo yokunyibilikisa, ukugalela kunye nezinye izixhobo, kunye neendibano zocweyo ezinkulu kunye nabasebenzi abaninzi, utyalo-mali olukhulu, iinkqubo ezininzi, iinkqubo zokuvelisa ezintsonkothileyo, kunye nongcoliseko lokusingqongileyo.Inqanaba lobugcisa labasebenzi lichaphazela ngokuthe ngqo umgangatho wemveliso.Ingxaki yokuvuza kwee-spherical capillary pores ayikwazi ukusonjululwa ngokupheleleyo, kwaye isibonelelo somatshini esingenanto sikhulu kwaye inkunkuma inkulu.

(2) Ukubumba

Le yenye indlela eyamkelwa ziinkampani ezininzi zeevalvu zasekhaya ngoku.Ineendlela ezimbini zokusetyenzwa: enye kukusebenzisa intsimbi engqukuva ukusika, ukufudumeza kunye nokwenza into engqukuva eqinileyo engenanto, kwaye emva koko wenze ukusetyenzwa koomatshini.Okwesibini kukubumba ipleyiti engqukuva yentsimbi engenasici kumatshini wokushicilela omkhulu ukuze ufumane indawo engenanto engenanto, kwaye emva koko umatshini welding engqukuva engenanto.Le ndlela inezinga eliphezulu lokusetyenziswa kwezinto, kodwa ifuna umatshini onamandla aphezulu.

(3) Ukusonta

Indlela yokusonta isinyithi yindlela yokuqhubela phambili kunye neechips ezimbalwa kwaye akukho chips, eyesebe elitsha lokulungisa uxinzelelo.), ukugcina ixesha elininzi lokucubungula (imizuzu eyi-1-5 yokwenza), kwaye amandla ezinto eziphathekayo anokuphinda aphindwe kabini emva kokujikeleza.Ngenxa yendawo encinci yoqhagamshelwano phakathi kwevili elijikelezayo kunye nomsebenzi ngexesha lokujikeleza, izinto zetsimbi zikwimeko yoxinzelelo lweendlela ezimbini okanye ezintathu, ekulula ukukhubaza, kwaye unxibelelwano lweyunithi ephezulu inokufumaneka. ngamandla amancinci.

Uxinzelelo (ukuya kwi-25-35Mpa), ngoko ke, izixhobo zilula, kwaye amandla afunekayo afunekayo amancinci (ngaphantsi kwe-1 / 5-1 / 4 yokushicilela), eye yaqatshelwa yi-valve yelizwe langaphandle njenge ukusetyenzwa kwesphere eyonga umbane Isicwangciso senkqubo sikwalungele ukusetyenzwa kwezinye iindawo ezijikelezayo ezingenanto.

Itekhnoloji yokusonta isetyenziswe ngokubanzi kwaye yaphuhliswa ngesantya esiphezulu kumazwe amaninzi.Itekhnoloji kunye nezixhobo zikhule kakhulu kwaye zizinzile, kwaye ulawulo oluzenzekelayo lokudibanisa oomatshini, umbane kunye ne-hydraulic iyafezekiswa.

Iimbonakalo

-Ubukhulu:l/4"-6"

-Investment Casting steel stainless ibhola

-Izinto zebhola CF8M CF8 CF3M

-Singavelisa zonke iintlobo zeebhola ngokweemfuno zabathengi bethu

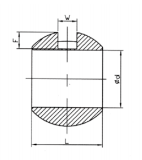

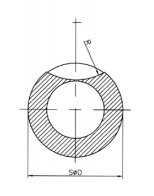

Ubungakanani:

| SΦD | Φd | L | W | F | R |

| 15.5 | 9.2 | 11.5 | 4 | 2.5 | 10 |

| 20.5 | 12.5 | 15.2 | 4 | 2.7 | 10 |

| 25.5 | 15 | 19.3 | 5 | 4 | 13 |

| 32 | 20 | 23.7 | 5 | 5 | 13.6 |

| 39 | 25 | 28.5 | 8 | 5.8 | 19 |

| 42.5 | 25 | 32.9 | 8 | 7 | 20 |

| 50 | 32 | 36 | 8 | 7 | 25 |

| 60 | 38 | 45 | 9.5 | 8 | 28 |

| 63 | 38 | 48.5 | 9.5 | 9 | 30 |

| 76.5 | 50 | 56 | 9.5 | 8.5 | 28 |

| 80 | 50.8 | 59.9 | 9.6 | 10 | 37.5 |

| 97 | 65 | 70.5 | 12 | 12 | 50 |

| 100 | 65 | 73.7 | 12 | 15 | 50 |

| 115 | 76 | 84.3 | 12 | 12 | 50 |

| 120 | 76 | 90 | 12 | 15 | 50 |

| 125 | 80 | 93.7 | 16 | 15 | 37.5 |

| 148 | 94 | 112 | 15 | 14 | 62.5 |

| 152 | 100 | 111.4 | 16 | 17 | 75 |

| 194 | 125 | 145 | 20 | 24 | 50 |

| 230 | 150 | 170 | 22 | 26 | 75 |

Uludwe Lwezinto:

| Uhlobo | C | Si | Mn | P | S | Cr | Ni | Mo |

| CF8M | ≤ 0.08 | ≤ 1.5 | ≤ 1.5 | ≤ 0.04 | ≤ 0.04 | 18.0 - 21.0 | 9.0 ~ 12.0 | 2.0 ~ 3.0 |

| CF8 | ≤ 0.08 | ≤ 2.0 | ≤ 1.5 | ≤ 0.04 | ≤ 0.04 | 18.0 - 21.0 | 8.0 ~ 11.0 |

|

| CF3M | ≤ 0.03 | ≤ 1.5 | ≤ 1.5 | ≤ 0.04 | ≤ 0.04 | 17.0 - 21.0 | 9.0 ~ 13.0 | 2.0 ~ 3.0 |

Umboniso weMveliso