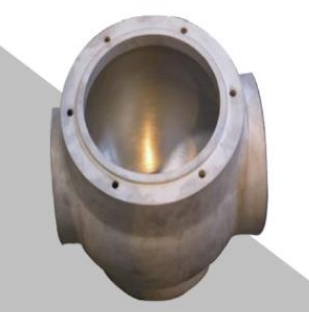

Forged High Pressure High Temperature Resistant Steel li qub

Muaj kev sib raug zoo forged steel kho series rau rooj vag valve, ntiaj teb valve thiab pob valve.Tuag forging yog siv rau DN15-DN80, thiab dawb forging yog siv rau ≥ DN80.Simultaneous multidirectional tuag forging (Hollow silver manufacturing technology) kuj maj mam siv rau high-end khoom.

Nta

1.Finite element tsom xam pab tsim kom ua tau zoo ntawm cov khoom muaj zog thiab qhov hnyav.

2.Welding bonnet, bolted bonnet thiab siab self sealing bonnet tuaj yeem muab raws li cov neeg siv khoom xav tau.

3.Raws li cov neeg siv khoom xav tau, peb tuaj yeem muab cov khoom loj-txoj kab uas hla ntau cov kev taw qhia tuag forging khoom.

4.Nws tuaj yeem npog tag nrho cov cam khwb cia steel series li qub ntawm lub tuam txhab, suav nrog hom valve, siab, txoj kab uas hla thiab cov khoom siv, hom kev sib txuas thiab kev sib kis.

Multi-direction tuag forging yog hais txog kev forging nrog cov duab complex, tsis muaj burr, me me multi ceg los yog kab noj hniav, uas yog tau los ntawm kev siv ua ke tuag, ib zaug cua sov thiab ib zaug stroke ntawm xovxwm.Tsis tas li ntawd, muaj qhov xav tau siab heev rau lub tonnage ntawm forging xovxwm.Yav dhau los, vim qhov loj ntawm txoj kab uas hla loj hloov lub cev, nws tsuas yog ua tau los ntawm kev faib nyiaj thiab ces sib sau ua ke thiab welded ua ke.Yog tias siv ntau txoj kev tuag forging, tsis tsuas yog cov duab tuaj yeem ncaj qha forged hauv ib lub tshav kub, tab sis kuj cov kab noj hniav sab hauv tuaj yeem ua ke, txhim kho lub zog thiab kev zoo nkauj ntawm qhov khoob hauv cov kev taw qhia fiber ntau, thiab txo cov nqi khoom. .

Cov txheej txheem sib txawv ntawm forged valve thiab cam khwb cia valve

Rau valve casting thiab valve forging, txhua txheej txheem muaj nws tus kheej zoo.Qee qhov project nyiam ib txoj hauv kev dua lwm qhov.Thiab lwm tus yog tsim nyog rau lwm tus neeg.Hauv qab no peb teev qhov sib txawv tseem ceeb ntawm casting thiab forging:

1. Lub zog sib txawv:

Cov ntaub ntawv cam khwb cia muaj lub zog tsawg vim tias lawv tau nchuav rau hauv cov kab noj hniav uas tso cai rau cov khoom tsim tawm dawb.

Cov ntaub ntawv forged muaj zog dua.Vim hais tias lawv muaj ib tug zoo-txhais qauv grain, compression los ntawm quab yuam tsub kom lawv txhua yam muaj zog.

2. Haum rau cov duab hollow

Casting feem ntau yog nyiam los tsim cov khoom uas muaj qhov hollow los yog kab noj hniav.

Forging excludes kab noj hniav thiab porosity los ntawm nws muaj pes tsawg leeg.

3. Lub uniformity yog txawv:

Casting cov ntaub ntawv tsis yog ib txwm homogeneous.

Cov ntaub ntawv forged tuaj yeem ua rau hauv cov duab zoo ib yam thiab tswj cov qauv sib xws.

4. Loj txwv:

Casting tsis muaj qhov loj me lossis cov duab txwv.Vim tias tag nrho cov ntaub ntawv yuav raug melted ua ntej tsim.

Cov ntaub ntawv hnyav txog li 50 kg tuaj yeem raug forged.Yuav tsum muaj lub zog siab dua yog tias cov khoom siv forged hnyav dua 50 kg.Hauv qhov no casting yuav yog lwm txoj hauv kev.

5. Kev nyuaj siab

Casting tuaj yeem tsim cov qauv thiab cov duab.Forging tsom ntau dua rau kev tsim cov khoom sib xws thiab cov ntaub ntawv yooj yim.

6. Cov nqi sib txawv:

Casting siv cov cuab yeej pheej yig.Cov tshuab siv rau forging, xws li hnyav industrial tuag, yog kim dua.

Qhov no yog ib daim ntawv tshawb fawb uas cov kws tshawb fawb ntawm University of Toledo piv qhov sib txawv ntawm ib yam khoom uas tsim nyob rau hauv ob txoj kev.Cov lus xaus hauv qab no tau teev tseg:

Lub zog tensile ntawm forgings yog 26% siab dua li ntawm castings.

Lub zog qaug zog ntawm forgings yog 37% siab dua li ntawm castings.

Lub zog ntawm cam khwb cia hlau tsuas yog 66% ntawm cov hlau wrought.

Cov forgings muaj 58% txo qis hauv cheeb tsam thaum rub mus rau qhov tsis ua haujlwm.Thaj tsam ntawm qhov casting raug txo los ntawm 6%.