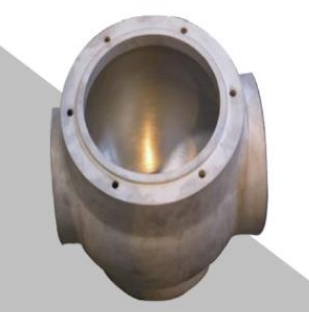

Ma Vavu Achitsulo Opangidwa ndi Kutentha Kwambiri Kwambiri Kutentha Kwambiri

Pali zofananira zosinthira zitsulo zopangira ma valve pachipata, valavu yapadziko lonse lapansi ndi valavu ya mpira.Die forging imagwiritsidwa ntchito pa DN15-DN80, ndipo forging yaulere imagwiritsidwa ntchito ≥ DN80.Simultaneous multidirectional die forging (Teknoloji yopangira siliva ya Hollow) imayikidwanso pang'onopang'ono pazinthu zapamwamba.

Mawonekedwe

1.Finite kusanthula kwazinthu kumathandizira kupanga kukhathamiritsa mphamvu yazinthu ndi kulemera kwake.

2.Boneti yowotcherera, bonati yokhala ndi bolted ndi pressure self sealing bonnet imatha kuperekedwa malinga ndi zomwe kasitomala amafuna.

3.Malinga ndi zofuna za makasitomala, titha kupereka zopangira zazikulu zamitundu yambirimbiri.

4.Ikhoza kuphimba ma valve onse opangidwa ndi zitsulo zamtundu wa kampani, kuphatikizapo mtundu wa valve, kuthamanga, m'mimba mwake ndi zinthu, njira yolumikizira ndi njira yotumizira.

Mipikisano malangizo kufa forging amatanthauza forging ndi mawonekedwe ovuta, popanda burr, yaing'ono Mipikisano nthambi kapena ndi patsekeke, amene analandira pogwiritsa ntchito pamodzi kufa, kamodzi kutentha ndi kamodzi sitiroko atolankhani.Kuphatikiza apo, pali chofunikira kwambiri pamakina osindikizira a forging.M'mbuyomu, chifukwa cha kukula kwakukulu kwa thupi lalikulu losintha m'mimba mwake, likhoza kupangidwa kokha pogawa siliva ndikusonkhanitsidwa ndi kuwotcherera pamodzi.Ngati Mipikisano Directional kufa forging ntchito, osati mawonekedwe akhoza mwachindunji anapeka mu kutentha umodzi, komanso patsekeke wamkati akhoza anamanga pamodzi, kwambiri kuwongolera mphamvu ndi aesthetics wa opanda kanthu mu malangizo CHIKWANGWANI, ndi kuchepetsa mankhwala mtengo. .

Kusiyana kwa njira pakati pa valve forged ndi cast valve

Pakuponyera ma valve ndi kupanga ma valve, njira iliyonse ili ndi ubwino wake.Ntchito zina zimakonda njira imodzi kuposa inzake.Ndipo winayo ndi woyenera kwa anthu ena.M'munsimu timatchula kusiyana kwakukulu pakati pa kuponyera ndi kufota:

1. Kusiyana kwamphamvu:

Zida zotayira zimakhala ndi mphamvu zochepa chifukwa zimatsanuliridwa muzitsulo zomwe zimalola kuti zinthuzo zizipanga momasuka.

Zipangizo zopeka ndizolimba.Chifukwa ali ndi chimanga chodziwika bwino, kukanikiza ndi mphamvu kumawonjezera mphamvu zamakina.

2. Oyenera mawonekedwe a dzenje

Kuponyera kumakonda kwambiri popanga zida zokhala ndi ming'alu kapena mabowo.

Kupanga kumapatula ma cavities ndi porosity kuchokera pamapangidwe ake.

3. Kufanana kumasiyana:

Zida zoponyera sizikhala zofanana nthawi zonse.

Zipangizo zopangidwira zimatha kupangidwa kuti zikhale zofanana ndikukhalabe zogwirizana.

4. Malire a kukula:

Kuyimba kulibe kukula kulikonse kapena malire.Chifukwa zida zonse zidzasungunuka zisanapangidwe.

Zida zolemera mpaka 50 kg zimatha kupangidwa mwachinyengo.Mphamvu yapamwamba imafunika ngati zinthu zopangidwira zikulemera kuposa 50 kg.Pankhaniyi, kuponyera kungakhale njira ina.

5. Kuvuta

Kuponya kumatha kupanga mapangidwe ovuta komanso mawonekedwe.Forging imayang'ana kwambiri pakupanga zida zofananira komanso zosavuta.

6. Mitengo yosiyanasiyana:

Kuponya kumagwiritsa ntchito zida zotsika mtengo.Makina omwe amagwiritsidwa ntchito popanga, monga kufa kwa mafakitale ambiri, ndi okwera mtengo kwambiri.

Ili ndi pepala lofufuza kumene ofufuza a ku yunivesite ya Toledo anayerekezera kusiyana pakati pa chinthu chimodzi chopangidwa m'njira ziwiri.Zotsatirazi zandandalikidwa:

Mphamvu zolimba za forgings ndi 26% kuposa za castings.

Mphamvu ya kutopa ya forgings ndi 37% kuposa ya castings.

Mphamvu zokolola za chitsulo chosungunuka ndi 66% yokha ya chitsulo chopangidwa.

Zopangazo zidachepetsedwa ndi 58% m'malo pomwe zidalephera.Dera loponyera linachepetsedwa ndi 6%.