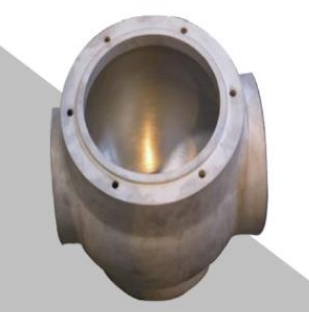

Forged High Pressure High Temperature Resistant Steel Valves

Kune inoenderana forged simbi inogadzirisa akatevedzana yegedhi vharafu, globe vharafu uye bhora vharafu.Die forging inoshandiswa DN15-DN80, uye forging yemahara inoshandiswa ≥ DN80.Simultaneous multidirectional die forging (Hollow sirivheri yekugadzira tekinoroji) inoiswawo zvishoma nezvishoma kune yakakwirira-kuguma zvigadzirwa.

Features

1.Finite element analysis yakabatsira dhizaini kuti iwedzere simba rechigadzirwa uye uremu.

2.Welding bonnet, bolted bonnet uye pressure self sealing bonnet inogona kupiwa maererano nezvinodiwa nevatengi.

3.Maererano nezvinodiwa nevatengi, tinogona kupa hombe-dhayamita yakawanda nzira inofa yekugadzira zvigadzirwa.

4.Inogona kuvhara mavharuvhu ose akakanda simbi yekambani, kusanganisira rudzi rwevharuvhu, kumanikidzwa, dhayamita uye zvinhu, nzira yekubatanidza uye nzira yekufambisa.

Multi direction die forging inoreva kuumba nechimiro chakaoma, pasina burr, diki diki davi kana ine mhango, iyo inowanikwa nekushandisa yakasanganiswa kufa, kamwe kupisa uye kamwe kamwe sitiroko yemuchina.Uyezve, pane chinodiwa chakanyanya kwazvo kune tonnage yefogi muchina.Kare, nekuda kwehukuru hukuru hweiyo dhayamita yakakura inogadzirisa muviri, inogona chete kugadzirwa nekukamura sirivheri uye wozounganidzwa uye wobatanidzwa pamwechete.Kana ma-multi-directional die forging akashandiswa, kwete chete chimiro chinogona kugadzirwa zvakananga mukupisa kumwe chete, asiwo mhango yemukati inogona kuumbwa pamwe chete, ichivandudza zvakanyanya simba uye aesthetics yechinhu chisina chinhu munzira yefiber, uye kuderedza mutengo wechigadzirwa. .

Process musiyano pakati forged vharafu uye cast valve

Pakukandira vharafu uye kugadzira vharafu, imwe neimwe nzira ine zvayakanakira.Mamwe mapurojekiti anosarudza imwe nzira pane imwe.Uye imwe yacho inonyanya kukodzera kune vamwe vanhu.Pazasi isu tinonyora misiyano mikuru pakati pekukanda nekugadzira:

1. Musiyano wesimba:

Zvinhu zvekukanda zvine simba rakaderera nekuti zvinodururwa mugomba rinobvumira kuti zvinhu zviumbe zvakasununguka.

Forged zvinhu zvakasimba.Nemhaka yekuti vane chimiro chezviyo chakanyatsotsanangurwa, kudzvinyirira nechisimba kunowedzera simba ravo remagetsi.

2. Inokodzera mhango maumbirwo

Casting inowanzofarirwa kugadzira zvinhu zvine nzvimbo dzisina maburi kana makomba.

Forging haisanganisi cavities uye porosity kubva pakuumbwa kwayo.

3. Kufanana kwakasiyana:

Zvinhu zvekukandira hazvisi nguva dzose zvakafanana.

Zvishandiso zvakaumbwa zvinogona kugadzirwa kuita chimiro chakafanana uye kuchengetedza chimiro chechimiro.

4. Saizi inogumira:

Casting haina chero saizi kana chimiro chinogumira.Nokuti zvinhu zvose zvichanyungudutswa zvisati zvagadzirwa.

Zvishandiso zvinorema kusvika 50 kg zvinogona kugadzirwa.Simba repamusoro rinodiwa kana zvinhu zvichagadzirwa zvichirema kudarika 50 kg.Muchiitiko ichi, kukanda kwaizove kwakasiyana.

5. Kuoma kunzwisisa

Kukandira kunogona kugadzira mapatani uye maumbirwo akaomarara.Forging inotarisa zvakanyanya pakugadzira yunifomu uye zvinhu zviri nyore.

6. Mari dzakasiyana:

Kukandira kunoshandisa midziyo isingadhure.Michina inoshandiswa kugadzira, senge inorema maindasitiri inofa, inodhura zvakanyanya.

Iri ipepa rekutsvagisa apo vaongorori vepaYunivhesiti yeToledo vakafananidza musiyano pakati pechigadzirwa chimwe chinogadzirwa nenzira mbiri.Mhedziso dzinotevera dzakanyorwa:

Iko kusimba kwesimba rekugadzira kune 26% yakakwirira kupfuura iyo yekukanda.

Iko kuneta kwesimba kwefogi kune 37% yakakwirira kupfuura iyo yekukanda.

Kusimba kwegoho resimbi yakakandwa inongova 66% yesimbi yakarukwa.

Iwo mafogi aive ne58% kudzikiswa kwenzvimbo paakadhonzwa mukutadza.Nzvimbo yekukanda yakaderedzwa ne6%.