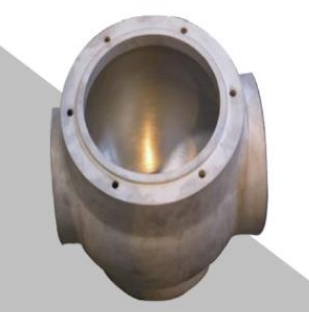

Iivalvu zentsimbi eziFakelwe kuxinzelelo oluphezulu lobushushu obuphezulu

Kukho uthotho oluhambelanayo lohlengahlengiso lwentsimbi yentsimbi yevalve yesango, ivalve yeglowubhu kunye nevalve yebhola.I-Die forging isetyenziselwa i-DN15-DN80, kwaye i-forging yamahhala isetyenziselwa ≥ DN80.Ngaxeshanye multidirectional die forging (Itekhnoloji yokuvelisa isilivere eHollow) iphinda isetyenziswe ngokuthe ngcembe kwiimveliso eziphezulu.

Iimbonakalo

I-1.I-finite element analysis incedise ukuyila ukwandisa amandla emveliso kunye nobunzima.

Ibhonethi ye-2.Welding, ibhonethi eboshiweyo kunye nebhonethi yokuzitywina yoxinzelelo inokubonelelwa ngokweemfuno zabathengi.

3.Ngokuhambelana nemfuno yabathengi, sinokubonelela ngeemveliso zokubumba ezinobubanzi obukhulu be-multi direction die.

I-4.Inokugubungela zonke ii-valve ze-steel ze-cast cast zenkampani, kubandakanywa uhlobo lwe-valve, uxinzelelo, ububanzi kunye nezinto eziphathekayo, imodi yokudibanisa kunye nemodi yokuhambisa.

Multi direction die forging forging ibhekisela ekubunjweni okunemilo entsonkothileyo, ngaphandle kwe-burr, isebe elincinci elincinci okanye elinomngxuma, elifunyenwe ngokusebenzisa ukufa okudityanisiweyo, ukufudumeza kunye nokubetha kanye kokushicilela.Ngaphezu koko, kukho imfuneko ephezulu kakhulu yetoni yokushicilela umshicileli.Ngaphambili, ngenxa yobukhulu obukhulu bomzimba omkhulu wokulungelelanisa, unokwenziwa kuphela ngokwahlula isilivere kwaye emva koko idityaniswe kwaye idityaniswe kunye.Ukuba i-multi-directional die forging isetyenziswa, kungekuphela nje imilo enokwenziwa ngokuthe ngqo kubushushu obunye, kodwa nomngxuma ongaphakathi unokubunjwa kunye, uphucula kakhulu amandla kunye nobuhle bendawo engenanto kwicala lefiber, kunye nokunciphisa ixabiso lemveliso. .

Umahluko wenkqubo phakathi kwevalve engumgunyathi kunye nevalve etyhidiweyo

Ukuphoswa kwevalve kunye ne-valve forging, inkqubo nganye ineenzuzo zayo.Ezinye iiprojekthi zikhetha indlela enye kunenye.Kwaye enye ifaneleka ngakumbi kwabanye abantu.Apha ngezantsi sidwelisa umahluko omkhulu phakathi kokusakha kunye nokwenza:

1. Umahluko wamandla:

Izinto zokuphosa zinamandla aphantsi ngenxa yokuba zigalelwa kwi-cavity evumela ukuba izinto zenze ngokukhululekileyo.

Izinto ezibunjiweyo zomelele.Ngenxa yokuba banesakhiwo esicacileyo sengqolowa, ukunyanzeliswa ngamandla kwandisa amandla abo omatshini.

2. Ifanelekile kwiimilo ezingenanto

Ukuphosa kukhethwa ngokubanzi ekuveliseni imathiriyeli eneendawo ezingenanto okanye imingxuma.

Ukubunjwa akubandakanyi imingxuma kunye ne-porosity ekuqulunqweni kwayo.

3. Ukufana kwahlukile:

Izinto zokuphosa azisoloko zifana.

Izinto ezibunjiweyo zingenziwa kwimilo ehambelanayo kwaye zigcine ukuhambelana kwesakhiwo.

4. Umda wobungakanani:

Ukusasa akunabungakanani okanye imida yokumila.Ngenxa yokuba zonke izixhobo ziya kunyibilika ngaphambi kokuba zenziwe.

Izinto ezinobunzima obufikelela kwi-50 kg zinokubunjwa.Amandla aphezulu afunekayo ukuba izinto eziza kwenziwa zinobunzima obungaphezu kwe-50 kg.Kule meko ukuphosa kuya kuba yenye indlela.

5. Ukuntsokotha

Ukuphosa kunokuvelisa iipateni ezinzima kunye neemilo.I-Forging igxile ngakumbi ekuveliseni izinto ezifanayo kunye nezilula.

6. Iindleko ezahlukeneyo:

Ukusasa kusebenzisa izixhobo ezingabizi kakhulu.Oomatshini abasetyenziselwa ukwenza umyinge, njengokufa kwemizi-mveliso enzima, babiza kakhulu.

Eli liphepha lophando apho abaphandi kwiYunivesithi yaseToledo bathelekisa umahluko phakathi kwemveliso enye eveliswe ngeendlela ezimbini.Izigqibo ezilandelayo zidweliswe:

Amandla e-tensile ye-forging yi-26% ephezulu kune-castings.

Amandla okudinwa kwe-forging yi-37% ephezulu kunaleyo ye-castings.

Amandla emveliso yentsimbi etyhidiweyo yi-66% kuphela yentsimbi ekhandiweyo.

I-forgings ibe ne-58% yokunciphisa indawo xa itsalwa ukuba ingaphumeleli.Indawo yokuphosa yancitshiswa nge-6%.